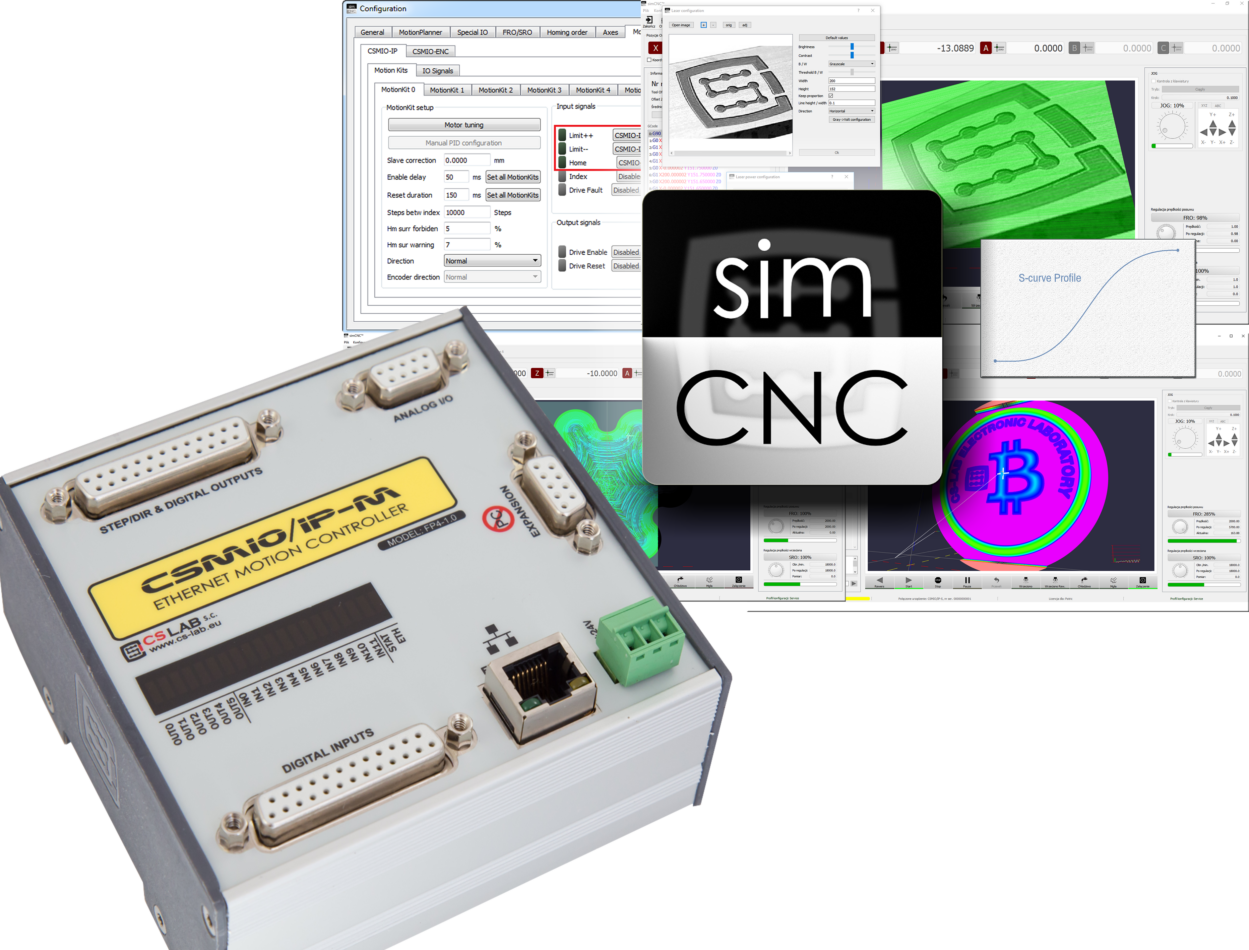

The ideal system for CNC machines control

CSMIO/IP-M is a 4-axis motion controller. In combination with a PC and simCNC control software, it’s an ideal system for CNC machine control. CSMIO/IP-M was designed for professionals, CNC automation manufacturers, retrofit specialists, and hobbyists who want to equip their machines with efficient, stable, and flexible CNC control systems. CSMIO/IP-M is for those who need as accurate and reliable controller as his bigger brother CSMIO/IP-S, spending much less (for more about CSMIO/IP-M supported features – read below).

How does it work?

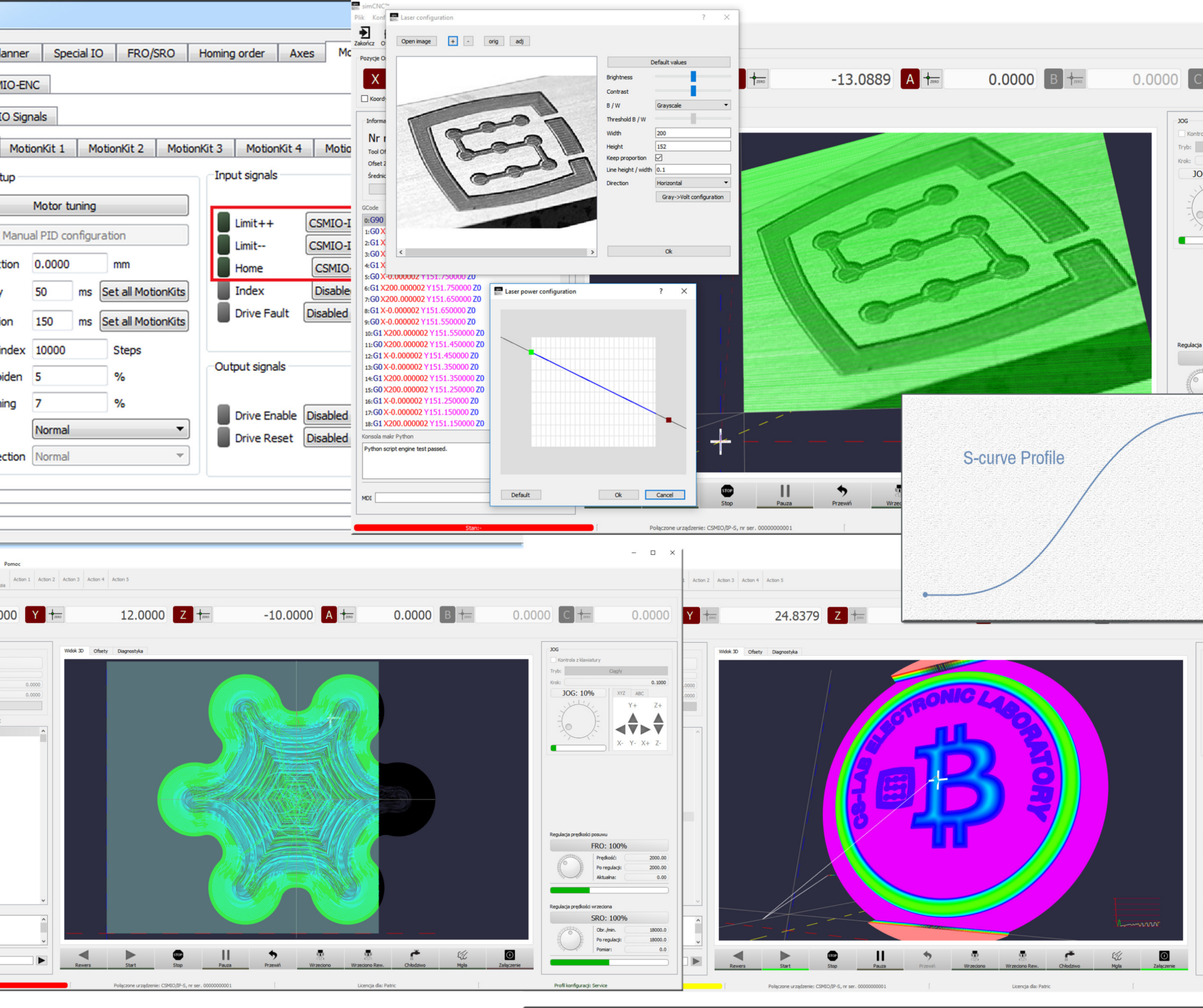

In short – the simCNC control software installed on a PC is the brain, and CSMIO/IP-M controller is the heart of the entire control system. the simCNC control software changes gcodes into motion trajectory and sends them to the CSMIO/IP-M through the network connection. Basing on the trajectory the controller generates an accurate step/dir signal for all axes. This division of tasks makes the PC less loaded.

Operation Stability is provided by connection with PC via Ethernet – its physical layer is galvanically isolated, and used protocols provide reliable and fast transmission even in a tough industrial environment). Practically any other interface does not provide continuity and reliability of transmission on such a high level as ETHERNET. That is why it is currently the worldwide standard for high-speed digital communication.

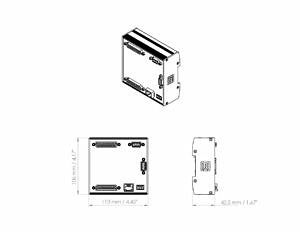

Easy installation – one of the biggest advantages of CSMIO/IP-M is the simplicity of installation. It does not require any external electronics for correct operation. Inputs/outputs signals are optically isolated, filtered, and protected against short circuits, overheating, etc. All signals are adapted to industry 24V standards. The device is enclosed in a compact housing and mounted on a DIN rail, which makes mechanical and electronic installation in a control cabinet take less time and is even easier.

CSMIO/IP-M controller is supported by professional, dedicated simCNC software. As for the control signal, the choice is the popular step/direction (step/dir) standard. This way, you can control both – stepper motor drives and the most modern servo drives. Thanks to the frequency of the stop signal that reaches up to 125KHz, you can apply adequate stepper division in stepper motors, reducing resonance and significantly improving the propulsion system’s performance. It also provides the full advantage of encoders with an average number of pulses per rotation (10.000 p/rev) and a large number of pulses per rotation using only a small electronic ratio.

The main advantages of the CSMIO/IP-M controller

- Step/dir signal – after the first run of a CNC machine equipped with the CSMIO/IP-M controller, you will notice how smooth and precise your motors’ work is. It’s thanks to high-quality step/dir signal and data buffer, which stores a small part of the trajectory sent by control software (simCNC, Mach3, Mach4).

- Data buffer – the mentioned trajectory buffer provides uninterrupted CNC machine operation, even in case of temporary problems with network connection or software control problems.

- Slave axis support – one slave axis support (without gantry geometry correction).

- Safety system – a very important advantage of the CSMIO/IP-M controller is its safety system. It constantly watches over the safety of a user and a machine. It consists of many independent algorithms and watchdogs that react quickly in forbidden or alarm situations. RESET support for axis drives. Support of FAULT signals from servo drives (immediate stop of a machine in case of any axis accident).

- Solid aluminum housing, which dissipates heat and protects electronic circuits very well. Readable led controls on a front panel make it easier to install and simplify diagnostics in case of any problems with switches or another external device that cooperate with the CSMIO/IP-M.

- Macros – you can control all digital and analog signals using Python (simCNC) macros.

- Industry-standard – the CSMIO/IP-M controller is adapted to worldwide standards applied by servo and stepper drives manufacturers, including:

- step/dir outputs supported by differential line transmitters DS26C31 (RS422 standard compliant)

- opto-isolated 24VDC digital outputs supported by specialized systems with protection against short-circuit and overload.

- opto-isolated 24VDC digital inputs

- 0-10V analog inputs are used to connect potentiometers of spindle rotation speed correction and axis feed rate.

- 0-10V analog outputs used, i.e., for VFD control.

Expansion modules

You can expand CSMIO/IP-M controller features using the CSMIO-MPG expansion module for manual axes operation and handwheel encoder. It provides very smooth control of machine motion and automatic switching between speed and position modes.

Attention:

CSMIO/IP-M controller does not support CSMIO-ENC and CSMIO-IO.

The housing of the CSMIO/IP-M controller and all the expansion modules is adapted to DIN 35mm rail mounting.

Main & Special Features

simCNC software (included) – read the complete description of the simCNC software.

CSMIO/IP-M – below the summary technical specification. The last column – CSMIO/IP-M.

|

PARAMETER |

CSMIO/IP-S |

CSMIO/IP-A |

CSMIO/IP-M |

| Number of axes | 6 |

6 |

4 |

| Digital inputs number |

32 |

24 |

12 |

| Digital outputs number |

16 |

16 |

4 |

| Relay outputs number |

– |

– |

2 |

| Analog inputs number |

4 |

4 |

2 |

| Analog outputs number |

2 |

6 (+/- 10V) |

2 |

| Supply voltage |

24VDC +/-10% |

24VDC +/-10% |

24VDC +/-10% |

| Power consumption |

5W |

5W |

5W |

| Maximum voltage on in/out lines |

30VDC |

30VDC |

30VDC |

| Maximum load of output line |

250mA |

250mA |

250mA |

| Voltage range of analog inputs |

0-10VDC |

0-10VDC |

0-10VDC |

| Maximum load of analog output |

5mA |

5mA |

5mA |

| Axis drives control type |

Step/Direction (STEP/DIR) |

Analog |

Step/Direction |

| Maximum frequency of STEP signal |

4MHz/8MHz |

– |

125kHz |

| STEP signal duty cycle |

50% |

– |

50% |

| PC connection type |

Ethernet 10/100Mb |

Ethernet 10/100Mb |

Ethernet 10/100Mb |

| Ambient temperature range |

0oC to +60oC |

0oC to +60oC |

0oC to +60oC |

| Relative humidity (without condensation) |

10% – 95% |

10% – 95% |

10% – 95% |

| CSMIO-MPG module support | |||

| CSMIO-IO module support | |||

| CSMIO-ENC module support | |||

| Backlash compensation | |||

| Homing on INDEX | |||

| Slave axes | |||

| THC analog mode | |||

| Spindle axis | |||

| #G32# threading | |||

| RIGID TAPPING | |||

| Spindle speed readout | |||

| Feedback |

CSMIO/IP-M is for those who need as accurate and reliable controller as his bigger brother CSMIO/IP-S, spending much less money. However, when designing a control system, they must be aware of what kind of features are supported by the CSMIO/IP-M and what their needs are.

CSMIO/P-M is recommended to users/companies who:

- retrofit original CNC machines that require fewer digital signals for basic signals support such as switches, E-Stop, Servo Alarm, Servo On, Servo Reset, or signals necessary to control a spindle (VFD).

- build new milling machines or any size routers that reach satisfactory speed and accuracy. For example, the CSMIO/IP-M controller allows achieving a frequency of 0.002mm and max. speed of the axis up to 15m/min. For most users, these parameters exceed their expectations from a CNC motion controller, which is so inexpensive.

- build plasma and laser cutters. In this field, the CSMIO/IP-M control is unquestionably successful. Its good price and capabilities are fully sufficient to handle this kind of machine.

CNC control system based on the CSMIO/IP-M controller can be extended using the additional module: CSMIO-MPG

CSMIO/IP-M can be successfully used with milling machines, lathes that don’t require threading features, routers, plasma, or laser cutters.

In the CSMIO/IP-M set you will get:

- CNC CSMIO/IP-M Controller

- Ethernet connection wire

- 1x 3 pin power plug

- 1xDB25 -> Terminal Block adapter

- 1xDB25 + 1xDB9 -> Terminal Block adapter

- 2xDB25 ribbon wire

- 1xDB9 ribbon wire

- simCNC software (license key sent in email)

![]()

Updates

simCNC Control Software

The device works with simCNC software by CS-Lab (included). SimCNC software doesn’t require any additional plugin. While we send your order by shipping carrier (FedEx, TNT, UPS, or DHL), you will receive the simCNC license in an email. SimCNC software doesn’t require any additional plugins.

Download simCNC software: simCNC DOWNLOAD. Install, open, and enter your license file into the Settings (configuration) menu.

Read more: simCNC Updates

CSMIO/IP Firmware (plugin) and Updates

CSMIO/IP controllers always have the newest firmware. Updates are done using the intuitive Firmware Update Utility. All the CSMIO/IP controllers have a bootloader on board, so there is no risk of damaging the device after the firmware update fails. SimCNC software doesn’t require any additional plugins to be used with CSMIO/IP.

firmware v3.xxx with a plugin for

Drivers supported

CSMIO/IP-M supports step/dir servo and stepper drivers.

CSMIO/IP-M supports simDrive servo drives available in CS-Lab’s store.

Download

simCNC software doesn’t require any additional plugins to be used with CSMIO/IP. Download simCNC software, documentation, and check the Changelog.

The CSMIO/IP controllers’ firmware is successively developed. All CS-LAB controllers have a bootloader installed, so there is no risk of hardware damage in the event of a failed software update. The update is carried out using an intuitive update wizard, it does not require knowledge of the hardware itself. SimCNC software does not require installing any additional plugins to work with CSMIO/IP.