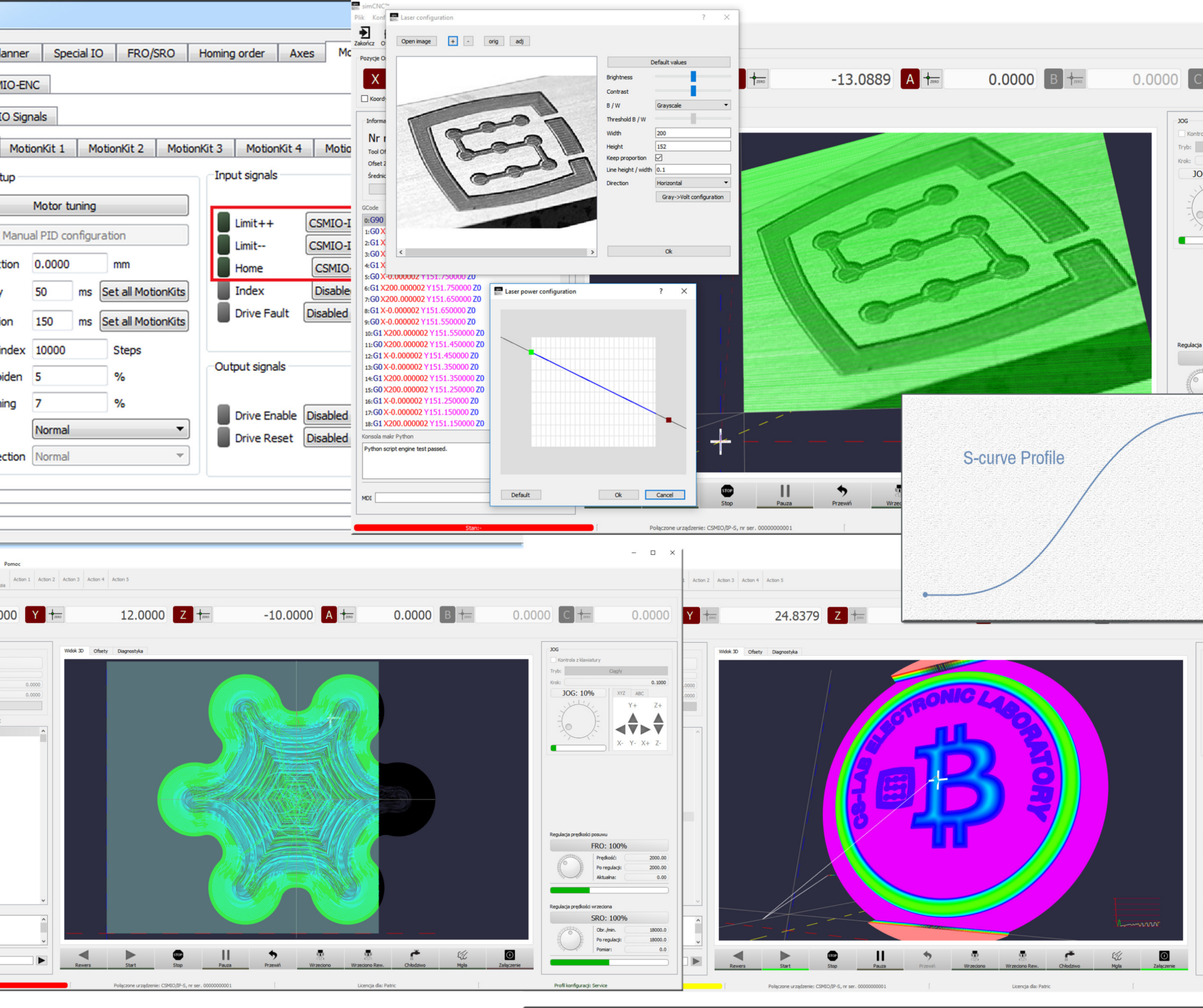

Innovative control software for CSMIO/IP controllers

The simCNC software provides dynamics and precision of motion not seen before in other proprietary CNC control software. Thanks to the S-curve profile and sophisticated algorithms for motion trajectory optimization, your CNC can be fast, dynamic, and precise. The processing is smooth and steady. It highly affects processing time and extends the tools and mechanics’ life. The simCNC software advantages:

-

- Advanced motion algorithms and increased precision

- S-curve velocity profile

- Python scripting language

- GUI editor

- Clear and structured configuration.

- Support for hybrid machines.

- Support for several operating systems.

Advanced GUI editor tailored to your requirements

simCNC software is equipped with an advanced graphical user interface GUI editor, allowing you to create your own original operator interfaces that are precisely tailored to customer requirements.

In conjunction with the Python scripting language and styling using the popular CSS, the editor allows you to create functional and visually attractive interfaces. The software code has been optimized in terms of performance to ensure responsiveness and comfort of use. SimCNC has a system of auto-layout and scaling graphic elements, which makes the designed interface more dynamic and able to adapt over a wide range to different sizes and resolutions of displays.

Since the simCNC software is multi-platform, the screen designs can be used without modification on Windows, macOS, and Linux.

More about simCNC software

The simCNC software is the result of our passion for numerical machines and years of hard work to achieve the ambitious goal – to create software that will provide users with the highest quality of movement, so far unprecedented in this price segment.

The program uses the popular, standard ISO G-Code trajectory description language, but when loading and working it analyzes every segment, arc or corner and practically recreates all shapes using advanced mathematical algorithms. Many variables are taken into account, such as given tolerance, speed, accelerations and type of curvature to generate data for the controller and axis drives in such a way that the movement is accurate, smooth and fast.

In many competing programs, motion is generated in such a way that the speed and position of the machine change smoothly but the acceleration changes in leaps and bounds. This is the so-called trapezoidal speed profile. At low acceleration values of 100-1000 mm/s2, it is not very noticeable, but it causes, among other things, a worse quality of the treated surface and faster wear of mechanical elements which perceive acceleration jumps as impacts. On the other hand, high accelerations (> 1000 mm/s2) are practically not used with the trapezoidal speed profile.

simCNC brings the quality to an incomparably higher level, because in its calculations it takes into account that the acceleration changes gradually. This is commonly referred to as the “S” speed profile. In practice, it often takes fractions of a second, but it makes a huge difference that can be felt on any machine tool – light, heavy, amateur or professional. Both on stepper and servo motors. In combination with the aforementioned advanced analysis and mathematical optimization algorithms, it allows to obtain excellent surface quality, shorten the machining time and significantly reduce the wear of the machine tool mechanics.

For all this, advanced electronics are required that can process the movement data stream in real time and transmit it to the axis drives without distortion. That is why we have also created a family of CSMIO/IP controllers that use Ethernet network connection for communication with the computer and are based on fast microprocessors, and some of them additionally use proprietary hardware solutions in specialized FPGA chips. By controlling both software and hardware, we are able to provide a complete system, the components of which fit perfectly together and which configuration is kept to a minimum.

The simCNC software was created on the basis of the newest solutions which allows it to work on all major system platforms: Windows, Linux and macOS. The software’s interface is fast and responsive, so that it is always ready at your beck and call – as befits a tool that you enjoy using.

simCNC requires CSMIO/IP hardware version FP4 (since late 2014). You can check the FP4 sign on a front panel of your CNC controller.

The simCNC software is valued by users all over the world for its high precision, simple configuration, the use of the S-curve profile, as well as sophisticated algorithms for optimizing the trajectory of motion.

The advantages of simCNC include:

- Advanced motion algorithms that ensure high precision and smooth motion translated into quality of surface of a processed detail.

- S-curve velocity profile, guaranteeing several times greater acceleration without audible knocking in a drive system.

- Increased precision in making corners with a simultaneous reduction in processing time. This effect is achieved thanks to configuring the corner cutting precision value from a gcode with the G64 P command (x is the precision value). This allows for a significant reduction in the roughing time and increasing precision of making corners during finishing.

- Python scripting language is the most popular and developed scripting language in the world. Thanks to this, you can find many tutorials and free libraries on the web that extend its capabilities.

- The screen editor built into simCNC allows you to create scalable screens in practicly any monitor format. It also has support for files and short CSS inserts, which open up new options for advanced programmers.

- Clear and structured configuration. All settings have been grouped thematically so that a user spontaneously draws attention to the options that should be set.

- Support for hybrid machines. SimCNC is created in such a way to allow you to build a machine that combines features of several machines. For example, simCNC enables you to create a multi-head machine that allows tangential knife cutting, cardboard bending, laser marking and glue application. Other examples are multi-spindle milling machines with several tool magazines or plasma drilling and cutting machines.

- Capability to export simCNC profile to a file and import from a file. This enables the simCNC software to be recreated on a new computer or a mass-produced machine in a few minutes. It is possible because the simCNC profile contains all settings, Python macros and the simCNC screen.

- Support for several operating systems. simCNC can successfully run on Windows, Linux, and MacOS (details in the Download tab). You can also run simCNC on a Raspberry Pi model B device with 4GB of RAM or more. This solution can be used for all average machines, except for high-speed devices working with high resolutions, where the computing power of the Raspberry Pi may not be sufficient.

SimCNC control software is designed for CNC machines with up to six axes. This limitation is due to the maximum number of axes supported by CSMIO/IP controllers. SimCNC software can be successfully used in CNC machines of the following types:

- Machines commonly known:

- universal 3-axis milling machines,

- 4-, 5- and 6-axis milling machines,

- gantry milling machines,

- machining centers for metals, composites, plastics,

- plasma cutters requiring THC support,

- gas cutters,

- coordinate drills,

- plotters

- routers

- lathes (coming soon),

- routers with tangential knife support and bending option,

- cutting and engraving lasers (engraving with dithering or shades of gray).

- Specialized machines:

- plasma cutters with pipe cutting support,

- plasma-gas cutters,

- plasma cutters with drilling option,

- multi-spindle milling machines (e.g. 3 main spindles and several drills) with support for side generators and saw attachments for cutting furniture boards,

- drill-cutters for PCB production,

- stacker for glue or sealants,

- milling machines with vacuum tables and retractable base pins,

- milling machines with two or more tables,

- multi-axis robots working in the Cartesian system,

- bending machines for wire and pipes.

The use of simCNC control software is very wide. It’s since simCNC software is created to be versatile and flexible. SimCNC software, thanks to its motion algorithms, provides an increase in efficiency, dynamics, and precision for each machine. It does not matter if the machine is:

- heavy or light,

- fast or slow,

- old or new,

- equipped with servo drives or stepper drives.

Updates in the case of simCNC can be considered another advantage, but they deserve a bit more discussion due to a few important things to know about.

- Update frequency. SimCNC software updates are scheduled on average every two months. If there is a significant number of patches, changes crucial for the stability of simCNC software or implementation of time-consuming functionalities, this period may be shortened or extended.

- No plugin. Unlike Mach3 and Mach4, simCNC does not use a plugin because it communicates directly with the CSMIO/IP controller. This is a huge advantage because it simplifies software and firmware design, minimizes the risk of errors, and relieves a user of the obligation to use a compatible plugin.

- Always the same software and firmware version. SimCNC software always stores a compatible firmware version for all CSMIO/IP controllers to save users’ time and unnecessary stress. If an incompatible firmware version has been previously installed in a controller, the simCNC software, at startup, will detect this fact and ask a user if he wants to change it to the right one.

- One thriving team of developers. In the case of simCNC, both software and firmware are created by the same team of developers. This solution is a huge advantage because it shortens the time of making corrections and implementing new functionalities. It is also worth mentioning that our programmers, thanks to this approach, have much more space and range of possibilities, and this results in the creation of well-functioning and unique features. The matter is entirely different in the case of Mach4 software because our developers have to follow the guidelines of developers of this software. This causes situations where, despite noticing some weak points of the Mach4 software, they can not do anything in this matter, and all they have to do is adapt, i.e., create a compatible plugin and firmware for CSMIO/IP controllers.

- Beta and alpha versions. In the case of an ordinary course of providing updates, before a new release of simCNC software is officially available, it must go through two stages. The first stage is the alpha phase, in which the simCNC software undergoes internal tests and possible corrections. The next stage is the beta phase, where the software is made available as a version for testing with the beta designation (unofficial). The planned duration of each stage is a minimum of one month, and only after passing both simCNC software is released officially.

- Emergency fixes. When a bug is revealed in the official version of simCNC, the entire development team must immediately perform the fix. If it is during a working week, the time to make a correction and release it should not be longer than several hours or so. If the error is insignificant and can be classified as cosmetic fixes, its removal will be implemented in the next simCNC software release.

- Customer suggestions and patching. If a user reports request/s for new functionality and it is qualified as useful for a significant number of users, it will be accepted for implementation. The process is similar when you submit a patch request. For the request to be accepted, it must undergo a verification process, that is, an attempt to reproduce the error on the test bench or machine. If the error is recreated, it is forwarded for deletion. In both cases (suggestions and corrections), the user always receives an approximate lead time and, if he is interested in a course of proceedings, also a ticket number. Based on the number, at a later time he can find out how the work progress looks like or possibly changes in their schedule. The numbers are also placed in a change log list.

Python Actions is a simple actions system that runs selected macros. The triggering action can be:

- change of digital input or output state,

- changes in a value of an analog input or output,

- timer,

- change of machine parameter values,

- many internal simCNC statuses.

In practice, Python actions allow you to create support for such functionalities as:

- start, stop, pause buttons etc.,

- control of a vacuum table,

- air extraction control,

- light barriers,

- central lubrication,

- a conveyor belt for removing chips.

Licence

- Download simCNC software here: DOWNLOAD simCNC for Windows, Linux, Mac

- Open simCNC software to see your CSMIO/IP controller connected in your network, its serial number, and MAC address.

- Order simCNC license by sending us the serial number and the MAC address of your controller via this online store or e-mail.

- You will get your simCNC license file key in an e-mail. Enjoy!

Detailed information about simCNC license purchase:

- One simCNC software license can be assigned to only one CSMIO controller.

- The simCNC software is available in DOWNLOAD section. For download and installation internet connection is required. Check the “run as administrator” in your operation system box if not selected previously.

- After you run the simCNC you’will see a list of your CSMIO/IP controllers including serial numbers and MAC addresses (restart if you can’t see the list).

- Enter the SN number and MAC address and add the license to your basket. If you don’t know the serial number nor the MAC address you can send them later to office@cs-lab.eu. Remember that without this information we are not able to send you the simCNC license key.

- If you are buying the simCNC license and a CSMIO controller at the same time and you don’t know the SN number and MAC address yet you can send us the SN number and MAC address after you get your CSMIO controller.

- You will get the license file in e-mail. The simCNC software can’t be further used without the valid license file.

- The simCNC license file should be used according to the instructions placed in an e-mail.

- You can use the full version of simCNC software for 3-month. You can get the 3-month license for one CSMIO/IP controller once a year.

Do you need to know more? Send us an e-mail: office@cs-lab.eu

Documentation on simCNC control software can be found at this link.