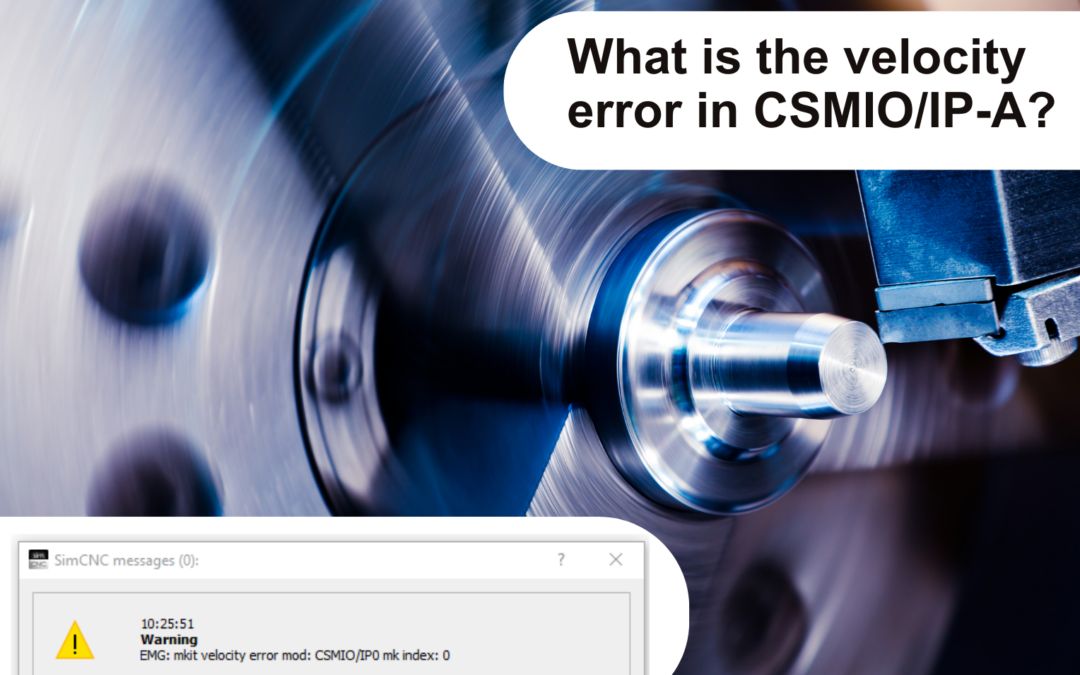

What is the Velocity Error in CSMIO/IP-A? This message means there is too significant a difference in speed between...

Two ways to test an analog output

May 11, 2023

Follow the CS-Lab Forum thread to learn more about the topic described below. You can test the analog...

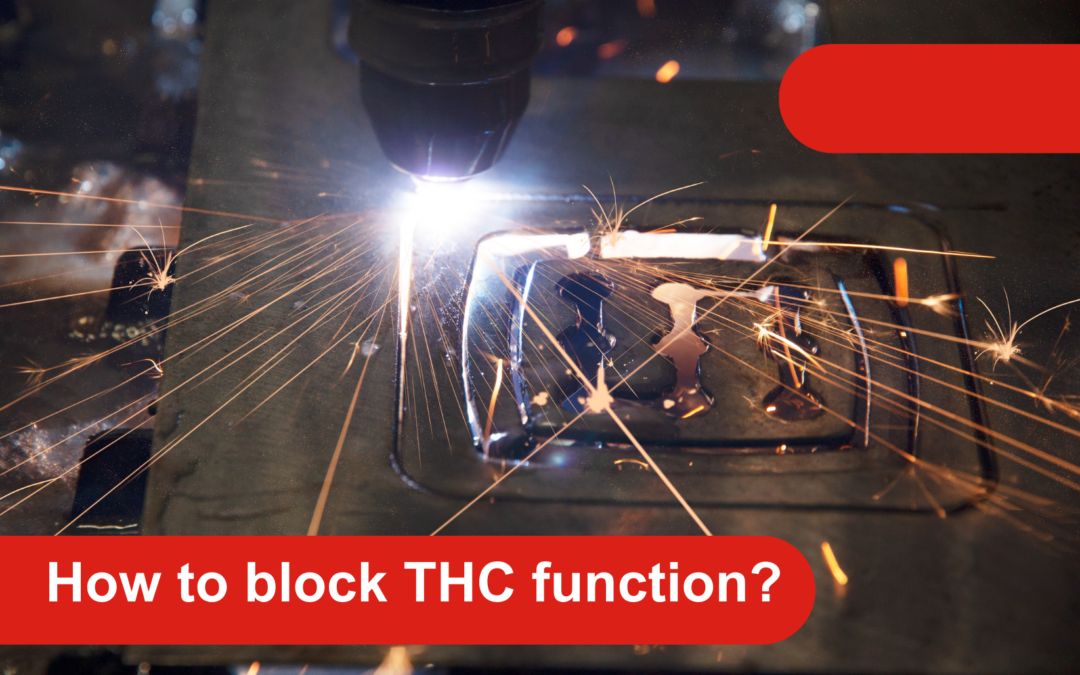

How to block THC function? – a short guide

Mar 31, 2023

How to block THC function? THC functions are blocked by setting the "Anti-dive vel. (%)" parameter to 100. To do...

The “PID Fault” (e-PID) and why it shows up.

Mar 23, 2023

What is the "PID Fault" (e-PID), and why it shows up? One of our customers received the error "PID Fault mkit:...

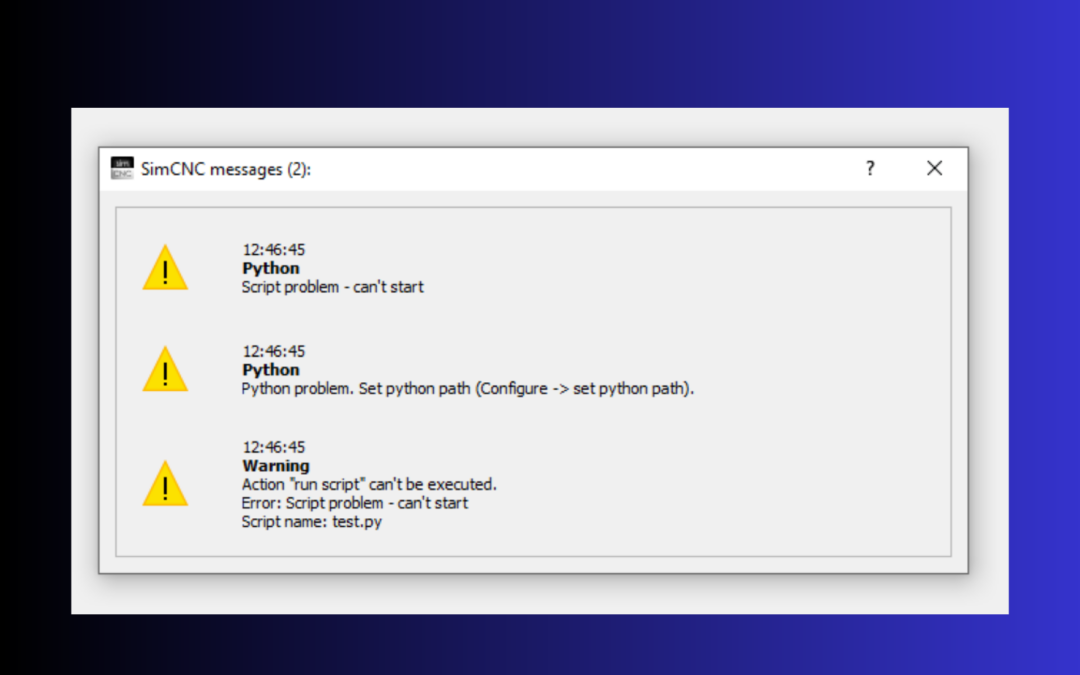

What causes Python path error?

Mar 10, 2023

The main question is, what did you do that caused this problem? This error occurs when: 1. You want to run...

CSMIO/IP-A and Rexroth Indramat ECODRIVE03 Driver with various CNC software

Feb 1, 2023

We created for you a connection diagram for CSMIO/IP-A and Indramat ECODRIVE03

Connection of CSMIO/IP-A controller with CD1-A INFRANOR drive (simCNC, Mach4)

Jan 7, 2021

Connection diagram of CSMIO/IP-A controller with CD1-A INFRANOR drive with simCNC and Mach4 software.

simCNC – the list of supported gcodes and mcodes

Apr 29, 2020

Description of the gcodes will be released soon. The definition of G2 / 3 is in accordance with the ISO standard.

VIDEO: How to install simCNC beta versions on Windows, MacOS, Ubuntu Linux

Sep 30, 2019

The short tutorial video presents how to add “beta” repository to install and test simCNC beta releases.

Connection of CSMIO/IP-M controller and JASD drive with Mach3

Jul 9, 2019

Connection diagram of CSMIO/IP-M controller and JASD drive with Mach3 software

Mach4 – CSMIO/IP analog inputs readout. RRO value control

May 30, 2019

If you want to control other values in Mach4 using an analog input we will show you how to do this.

simCNC Quickstart guide in Spanish, French, German and English

Oct 9, 2018

simCNC motion control software guides