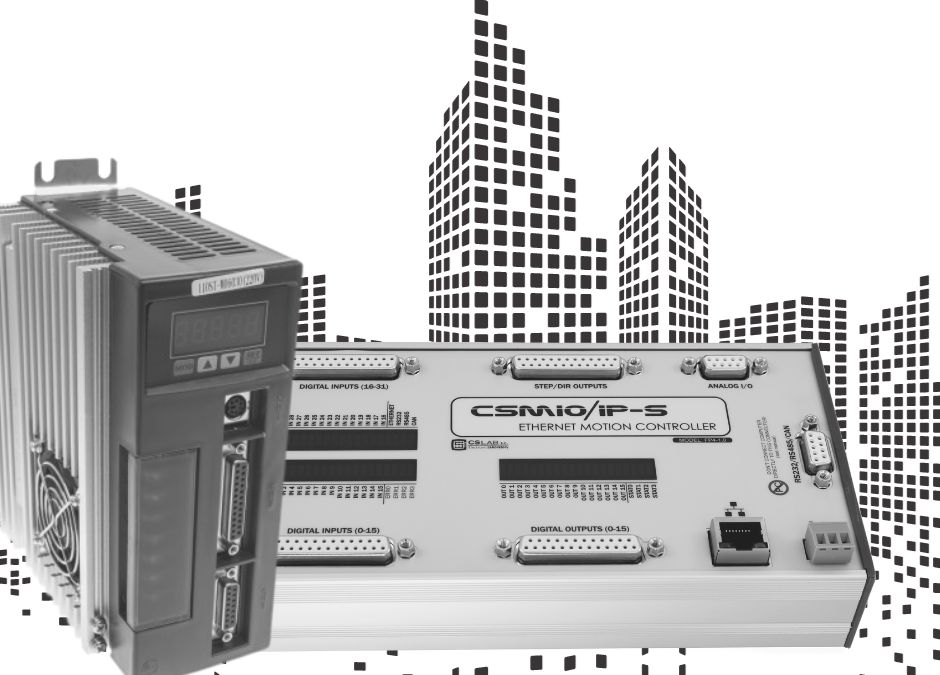

Connection diagram of CSMIO/IP-A controller and TRIO DX3 driver (documentation) with various of software.

Connection diagrams of CSMIO/IP-S controller, simCNC software and T3D driver

Mar 19, 2024

Connection diagram of the CSMIO/IP-S controller with the simCNC software and T3D drives (documentation)

CSMIO/IP-S Motion controller with DELTA B2 servo drives with limit switches and gantry

Mar 19, 2024

The connection diagram presents CSMIO/IP-S motion controller with DELTA B2 servo drives and simCNC software. Includes limit switches and gantry.

Connection diagrams of CSMIO/IP-S controller, simCNC software and JMC JAND driver

Feb 29, 2024

1. Connection diagram of CSMIO/IP-S controller, simCNC software and JMC JAND driver (documentation) Open the PDF...

Connection diagrams of CSMIO/IP-S and VFD by Sinovo (simCNC, Mach3, Mach4)

Feb 19, 2024

Connection of CSMIO/IP-S and Sinovo VFD with various CNC software.

Connection diagram of CSMIO/IP-S controller, simCNC software vs AASD 30A drivers

Jan 12, 2024

Here we present the connection diagram for CSMIO/IP-S controller, simCNC software and AASD 30A drivers Open the PDF...

CSMIO/IP-M and simDrive Servo 400W, 750W (Mach3, Mach4, simCNC). Connection and settings.

Nov 28, 2023

Connection diagram of the CSMIO/IP-S controller, simDrive 400V, 750V servo drive (v2) and Mach4 software

Look Ahead. How many lines of gcode does simCNC analyse in advance?

Nov 20, 2023

How many lines of gcode does simCNC analyse in advance? How many lines look ahead can we set? This question has...

Preparing a computer for the installation of simCNC, Mach3 and Mach4

Jul 28, 2023

Preparing a computer for the installation of simCNC, Mach3 and Mach4 Below is a list of activities that should be done...

CSMIO/IP-S Motion controller with DELTA A2 servo drives, limit switches

Jul 11, 2023

The connection diagram presents CSMIO/IP-S motion controller with DELTA A2 servo drives and simCNC software. It includes version with limit switches.

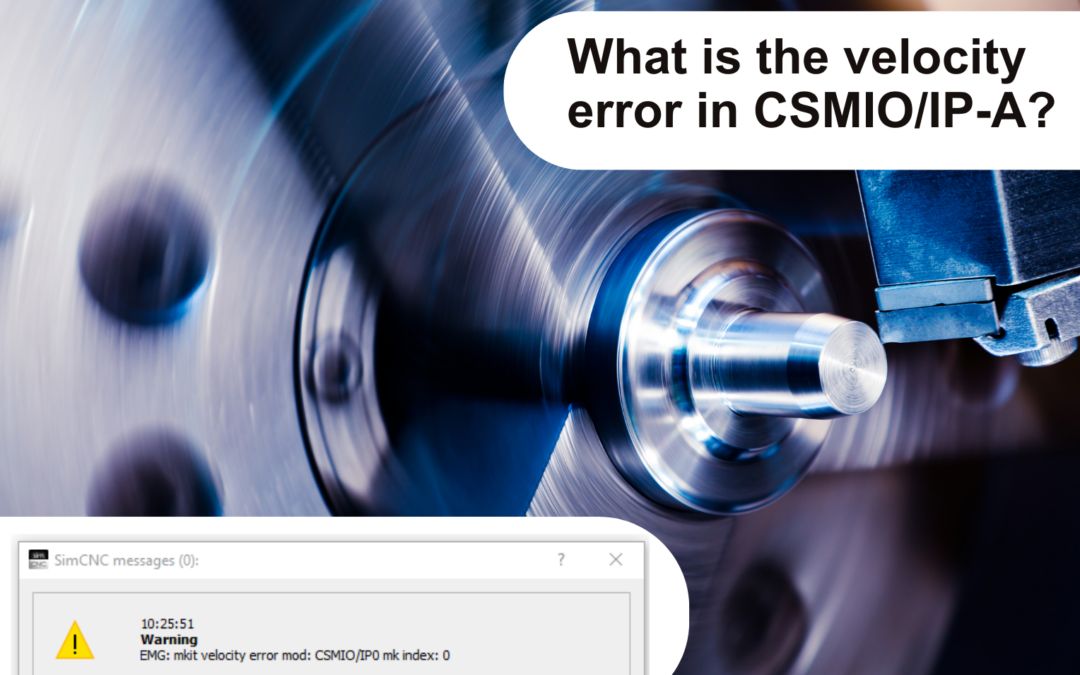

What is the Velocity Error in CSMIO/IP-A?

May 25, 2023

What is the Velocity Error in CSMIO/IP-A? This message means there is too significant a difference in speed between...

Two ways to test an analog output

May 11, 2023

Follow the CS-Lab Forum thread to learn more about the topic described below. You can test the analog...