CS-Lab Support Forum for CNC Community

Help to run this brand-new forum and stay with us.

Ask your questions, we are here to help!

my new screen vertical

Quote from CS-Lab Support on 18 January 2024, 07:57Quote from carbonkid on 16 January 2024, 21:15>>> For the time of the spindle warm-up I have now added an extra lineEdit at the top left next to the end button where this countdown expires.>>> Maybe that's a better idea like in the python console.

This issue has now been fixed. The fix will be available soon in 3.503 Beta 3 release.

>>> Another question. Would it be possible to display the tool table permanently on the screen,

>>> like the offset table? I have enough space for this on my tool management tab.

Unfortunately not. The tool table is a pop-up window, not a GUI object. If you want to add a tool table to your screen, you must create it yourself. Add multiple 'Line Edit' to the screen and set 'Input' and 'Output' to 'Machine Param'.

Machine parameters describing subsequent tools are in the range 6018 (tool number 1) - 8057 (tool number 255).

It is a simple, although time-consuming process, but it gives you freedom of action and modification.

Regards,

Quote from carbonkid on 16 January 2024, 21:15

>>> For the time of the spindle warm-up I have now added an extra lineEdit at the top left next to the end button where this countdown expires.

>>> Maybe that's a better idea like in the python console.

This issue has now been fixed. The fix will be available soon in 3.503 Beta 3 release.

>>> Another question. Would it be possible to display the tool table permanently on the screen,

>>> like the offset table? I have enough space for this on my tool management tab.

Unfortunately not. The tool table is a pop-up window, not a GUI object. If you want to add a tool table to your screen, you must create it yourself. Add multiple 'Line Edit' to the screen and set 'Input' and 'Output' to 'Machine Param'.

Machine parameters describing subsequent tools are in the range 6018 (tool number 1) - 8057 (tool number 255).

It is a simple, although time-consuming process, but it gives you freedom of action and modification.

Regards,

Quote from carbonkid on 18 January 2024, 10:25This issue has now been fixed. The fix will be available soon in 3.503 Beta 3 release.

Great, then there are both options now.

Unfortunately not. The tool table is a pop-up window, not a GUI object. If you want to add a tool table to your screen, you must create it yourself. Add multiple 'Line Edit' to the screen and set 'Input' and 'Output' to 'Machine Param'.

Machine parameters describing subsequent tools are in the range 6018 (tool number 1) - 8057 (tool number 255).

It is a simple, although time-consuming process, but it gives you freedom of action and modification.

OK, thanks, I'll do it that way. If I don't get it, I know where to ask. 😉

Regards

This issue has now been fixed. The fix will be available soon in 3.503 Beta 3 release.

Great, then there are both options now.

Unfortunately not. The tool table is a pop-up window, not a GUI object. If you want to add a tool table to your screen, you must create it yourself. Add multiple 'Line Edit' to the screen and set 'Input' and 'Output' to 'Machine Param'.

Machine parameters describing subsequent tools are in the range 6018 (tool number 1) - 8057 (tool number 255).

It is a simple, although time-consuming process, but it gives you freedom of action and modification.

OK, thanks, I'll do it that way. If I don't get it, I know where to ask. 😉

Regards

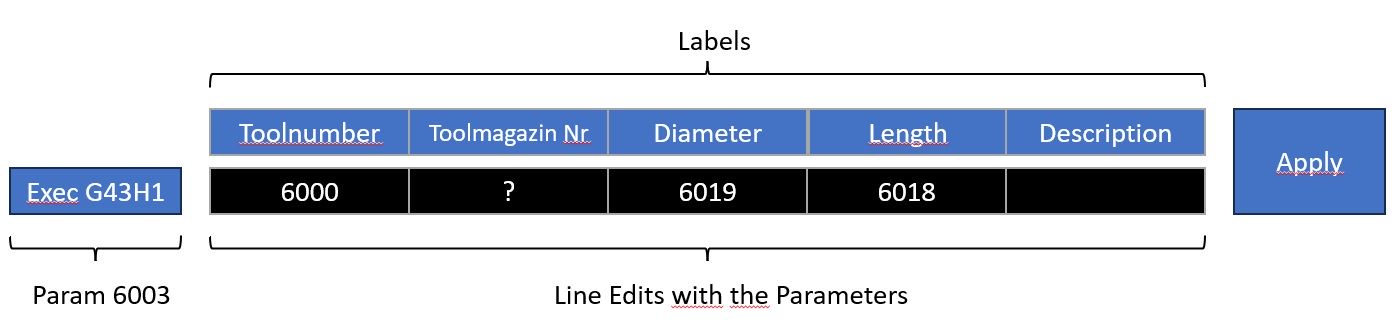

Quote from carbonkid on 18 January 2024, 21:05Before I start the hard work, it's better to ask first. 😉 Please take a look at the picture...is that correct (example for tool 1)? Tool magazine number can be any parameter that you then enter into your m6 script when the tool is changed automatically, true? Is there a script for the Apply button? Maybe you can give me an example of what needs to be selected for “Input Text” and “Output: return pressed” for the respective line edits.

Before I start the hard work, it's better to ask first. 😉 Please take a look at the picture...is that correct (example for tool 1)? Tool magazine number can be any parameter that you then enter into your m6 script when the tool is changed automatically, true? Is there a script for the Apply button? Maybe you can give me an example of what needs to be selected for “Input Text” and “Output: return pressed” for the respective line edits.

Uploaded files:Quote from CS-Lab Support on 22 January 2024, 12:53The topic of the tool table is a bit tricky because everyone has a different approach to it. What you may like may not be acceptable to another person. Therefore, I will not impose any solutions on you, but I will only refer to your idea:

1) The "Apply" button is not needed because the action on the parameters is immediate and does not require confirmation.

2) For Exec G43H… you used the correct parameter number. Clicking this button should trigger a macro calling the command d.setMachineParam( 6003, x )

3) If you want to have a button similar to Exec G43H... but related to the tool number in the spindle, then you should use parameter 6002. In this case, as in the previous point, you should use the macro (d.setMachineParam( 6002, x )

4) The tool number is a matter of convention or table concept and I have no comments here.

5) The rest of the table cells are fine.

The topic of the tool table is a bit tricky because everyone has a different approach to it. What you may like may not be acceptable to another person. Therefore, I will not impose any solutions on you, but I will only refer to your idea:

1) The "Apply" button is not needed because the action on the parameters is immediate and does not require confirmation.

2) For Exec G43H… you used the correct parameter number. Clicking this button should trigger a macro calling the command d.setMachineParam( 6003, x )

3) If you want to have a button similar to Exec G43H... but related to the tool number in the spindle, then you should use parameter 6002. In this case, as in the previous point, you should use the macro (d.setMachineParam( 6002, x )

4) The tool number is a matter of convention or table concept and I have no comments here.

5) The rest of the table cells are fine.

Quote from carbonkid on 22 January 2024, 21:57The topic of the tool table is a bit tricky because everyone has a different approach to it. What you may like may not be acceptable to another person. Therefore, I will not impose any solutions on you, but I will only refer to your idea:

Yes, you are right and thank you for your help. I'll try it that way.

The topic of the tool table is a bit tricky because everyone has a different approach to it. What you may like may not be acceptable to another person. Therefore, I will not impose any solutions on you, but I will only refer to your idea:

Yes, you are right and thank you for your help. I'll try it that way.

Quote from carbonkid on 29 January 2024, 17:48Quote from erwan on 14 January 2024, 13:56That's why I'm sharing it; those who don't know how to code should be able to use it without making any modifications. Well, you just need to configure the 'probig.py' file comming with simcnc.

and modify table size/speed at the beging of the code

Is there anything that my code doesn't do that you need?

by the way "CS-Lab Support" your 3D pro XYZ is howsome!

@erwanlefoll56

Hi, huge thanks to you! I've been working on your M6 script and the position for the manual tool change all weekend. It's truly an emotional rollercoaster of programming as a beginner. Now I've managed to turn yours and my previous m6 script into one... and it works. In my screen you enter various parameters which the script then uses. This is so much easier for every user than having to write around in the scripts. At home in the simCNC simulation everything works and I'm still testing it on the machine these days. The problems are slowly being solved, Now the priority is the last measurement cycle. Rectangle outer contour taking into account the rotation on the machine table and the workpiece zero point in the middle. The calculation is not easy but with the help of ChatGPT I will manage it.

I hope to be able to make the second video on my screen soon so that I can then share it publicly.

Quote from erwan on 14 January 2024, 13:56That's why I'm sharing it; those who don't know how to code should be able to use it without making any modifications. Well, you just need to configure the 'probig.py' file comming with simcnc.

and modify table size/speed at the beging of the code

Is there anything that my code doesn't do that you need?

by the way "CS-Lab Support" your 3D pro XYZ is howsome!

Hi, huge thanks to you! I've been working on your M6 script and the position for the manual tool change all weekend. It's truly an emotional rollercoaster of programming as a beginner. Now I've managed to turn yours and my previous m6 script into one... and it works. In my screen you enter various parameters which the script then uses. This is so much easier for every user than having to write around in the scripts. At home in the simCNC simulation everything works and I'm still testing it on the machine these days. The problems are slowly being solved, Now the priority is the last measurement cycle. Rectangle outer contour taking into account the rotation on the machine table and the workpiece zero point in the middle. The calculation is not easy but with the help of ChatGPT I will manage it.

I hope to be able to make the second video on my screen soon so that I can then share it publicly.

Quote from CS-Lab Support on 15 February 2024, 08:06Quote from carbonkid on 12 February 2024, 20:05Edit: delete

Solved?

Quote from carbonkid on 12 February 2024, 20:05Edit: delete

Solved?

Quote from carbonkid on 17 February 2024, 19:34Quote from CS-Lab Support on 15 February 2024, 08:06Quote from carbonkid on 12 February 2024, 20:05Edit: delete

Solved?

Yes, solved, the measurement now works perfectly including G68 rotation, that cost a lot of nerves!

Now for the next one...maybe you can give me a hint. In all of my measuring cycles, the Z height is measured first and then the respective contour. Now I want a checkbox, if this is checked, this measured Z value should not be set as zero but should be discarded. I can still imagine how to query the checkbox, but which command do I use to say that the measured value is discarded.

There should also be a second checkbox where you can click the check mark to reject the measurement of the contour so that you can only measure the size of a hole or a pin and not reset the zero point. I hope you all know what I mean.

Quote from CS-Lab Support on 15 February 2024, 08:06Quote from carbonkid on 12 February 2024, 20:05Edit: delete

Solved?

Yes, solved, the measurement now works perfectly including G68 rotation, that cost a lot of nerves!

Now for the next one...maybe you can give me a hint. In all of my measuring cycles, the Z height is measured first and then the respective contour. Now I want a checkbox, if this is checked, this measured Z value should not be set as zero but should be discarded. I can still imagine how to query the checkbox, but which command do I use to say that the measured value is discarded.

There should also be a second checkbox where you can click the check mark to reject the measurement of the contour so that you can only measure the size of a hole or a pin and not reset the zero point. I hope you all know what I mean.

Quote from CS-Lab Support on 20 February 2024, 08:56To interact with a macro, you can use three ways:

1) Place several objects on the simCNC screen to provide information and choices to a user.

However, this method is a bit risky because it requires a constant pattern of macro operation and, during changes, requires changing the screen and changing the macro.

2) MSG class. This is a class of pop-up windows with simple questions or warnings:

3) Create your macro popup with any content.

For this purpose, use the "tkinter" library.

In the attached macro, observe the console after it runs.

Enter a numerical value in the pop-up window, confirm, and close the window.

To interact with a macro, you can use three ways:

1) Place several objects on the simCNC screen to provide information and choices to a user.

However, this method is a bit risky because it requires a constant pattern of macro operation and, during changes, requires changing the screen and changing the macro.

2) MSG class. This is a class of pop-up windows with simple questions or warnings:

3) Create your macro popup with any content.

For this purpose, use the "tkinter" library.

In the attached macro, observe the console after it runs.

Enter a numerical value in the pop-up window, confirm, and close the window.