CS-Lab Support Forum for CNC Community

Help to run this brand-new forum and stay with us.

Ask your questions, we are here to help!

SimCNC Questions

Quote from dromeister on 3 October 2023, 23:16Hey,

I couldn't find some answers to questions I had about SimCNC, so I thought i would post here to make sure it works for me before going all in on hardware. Perhaps others have these questions as well.

1) What are the hardware recommendations for SimCNC software? I note that its possible to run on raspberry Pi, but I assume it would run better on higher-end hardware?2) Is it possible to use SimCNC to do PID position control based on external linear scales? See pg48 of quick start guide for setup idea. Seems like there is internal PID functionality to run the speed control loops of the CSMIO/IP-A.3) Can SimCNC do spline matching optimizations? I know OpenCN has done some really cool open-source optimizations for toolpaths and curious if something comparable is in the advanced motion features referenced by the marketing material of SimCNC.4) Is S-curve applied in both exact stop, and CV modes? Can it be adjusted via G-code/post-processor? Ie, "precise mode" or "coarse mode". I see that curve matching precision can be changed via G64, but curious if other aspects could be.5) Does SimCNC support, or plan to support, EtherCat or Modbus? I see from the forum that perhaps modbus could be implemented via python, but Ethercat obviously couldn't. Ethercat seems to be the future direction of modern servo controls. I have a whole set of ethercat B3 servos that I'd love to use, and VFD's over modbus are infinitely easier to deal with.6) Can SimCNC home from absolute encoders in any way?7) Is there a public location to view existing tickets and roadmaps to see where the development direction is?8) Is there a timeline on release of new hardware?Overall the software looks very promising. I have used Linuxcnc, UCCNC, and Centroid, and this certainly has the potential to exceed them all. S-curve implementation is a total game-changer in this market level. I looked at CSMIO products and SimCNC 2-3 more casually years ago, and your dev team has made serious progress on this in that time, which is more than can be said of most competing products. Kudos for that.

Hey,

I couldn't find some answers to questions I had about SimCNC, so I thought i would post here to make sure it works for me before going all in on hardware. Perhaps others have these questions as well.

Quote from CS-Lab Support on 5 October 2023, 08:441. The following should be considered as a minimum:

- 6th generation i3 processor

- 8GB RAM

- SSD drive.

- integrated graphics card

Such equipment is sufficient in 90% of cases.

If you are a professional and have a super precise and fast engraving machine or use long-term HSM processing, you should think about a more efficient processor, and especially a larger RAM. The fast and complicated path requires more processing power from a computer but the long and complicated path requires much more RAM. A path that is too long and complicated may cause RAM to overflow, which leads to Windows dumping data to a hard drive. If the hard drive or motherboard is too slow, it may overload the Windows system and thus cause intermittent simCNC operation. To prevent this from happening, 16GB or even 32GB RAM is used.

In the case of 3-axis machines for general use, you can try to use Raspberry Pi 4B. Typically, Raspberry Pi 4B is sufficient for such machines with a considerable margin.

2. Yes, you can use measuring scales, but the question is why do you want to do it? If you intend to use this solution to get rid of, for example, the problem of non-uniform pitch of a ball screw, this is a good idea. On the other hand, if your problem is a large backlash in a drive system, the use of measuring scales is not the solution.

3. In this respect, simCNC is unimaginably advanced. The optimization and precision feature is responsible for smooth and precise movement in simCNC.

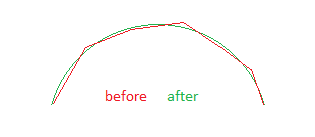

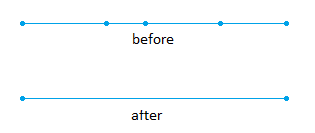

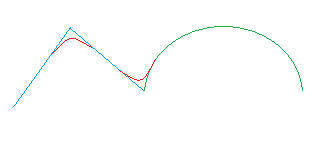

a) The optimization function works in several stages:

- removing micro sections with a different vector.

- converting any number of sections into arcs.

- converting any number of short segments with the same vector into a long segment.

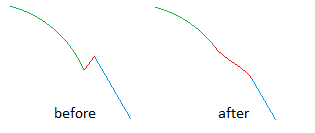

b) The precision feature is responsible for connecting all remaining corners after the optimization feature with a polynomial arc.

The amount of rounding (in red) depends on the value of the set feed (parameter "F" in gcode), acceleration and axis travel, but can never be greater than the precision value. The precision value is set once in the simCNC settings or dynamically changed from the gcode level to the "G64 P..." command. For example, if you use the G64 P0.2 command, a corner in the toolpath can be rounded by a maximum of 0.2mm. Please note that we are talking about the tool path, not the detail contour, these two values are separated by the tool radius. This means that the actual rounding of the edge of the detail also depends on a diameter of the cutter.

>> Is S-curve applied in both exact stop, and CV modes?

4. The S curve is always used because it determines the dynamics of a drive, not the dynamics of a tool path.

>> Can it be adjusted via G-code/post-processor? Ie, "precise mode" or "coarse mode". I see that curve matching precision can be changed via G64,

Yes, you can use the G64 P.. command to specify the type of machining

For example:

G64 P0.5 – rough machining

G64 P0.02 – finishing (remember what I wrote at the end of point number 3)

G64 P0 – exact stop

>>but curious if other aspects could be

Physics and geometry preclude many parameters that you could manipulate from gcode.

>> Does SimCNC support, or plan to support, EtherCat or Modbus?

5. The implementation of EtherCat has been temporarily suspended due to poor availability of electronic components needed for the production of the new CSMIO/IP-EtherCat controller.

We do not currently implement Modbus in simCNC because only advanced clients use it. When we have enough time and an idea on how to implement Modbus in a friendly way for all users, we will do it. The point is that we don't want to make the same mistakes as the competition (according to our customers' reports).

6. At the moment no. This will be possible when we implement EtherCat or introduce our new simDrive drivers with support for servo motors equipped with absolute encoders.

7. The implementation plan is determined by priorities, the more users need a given feature, the greater the priority. We are currently striving to ensure that simCNC fully supports all popular machines. Currently, we do not yet have lathe and threading support, which we plan to implement in the fall.

8. We plan to release some new equipment that will cause quite a shock for customers in this price range. The first to be released is the simDrive V3 drive, which will be attractive due to:

- simBus bus instead of step/dir (huge increase in the quality of the set motion and no more lost pulses)

- encBus instead of an incremental encoder signal (no more lost pulses)

- 131k encoder instead of 10k (more pulses allow you to speed up PID regulators)

- faster PID regulators

- huge increase in precision thanks to all the above points

- built-in 3.7V cell charger

- absolute encoders

- battery backup for encoders (no more machine homing)

- new generation intelligent autotuning

- monitoring the drive load from simCNC

Secondly, a motion controller with a huge dynamically filled trajectory buffer and a more efficient processor will be released. This will allow the machine to operate uninterrupted even if the computer is restarted or freezes.

Thirdly, the motion controller mentioned above will be upgraded to the EtherCat version.

Thank you for your appreciation.

1. The following should be considered as a minimum:

- 6th generation i3 processor

- 8GB RAM

- SSD drive.

- integrated graphics card

Such equipment is sufficient in 90% of cases.

If you are a professional and have a super precise and fast engraving machine or use long-term HSM processing, you should think about a more efficient processor, and especially a larger RAM. The fast and complicated path requires more processing power from a computer but the long and complicated path requires much more RAM. A path that is too long and complicated may cause RAM to overflow, which leads to Windows dumping data to a hard drive. If the hard drive or motherboard is too slow, it may overload the Windows system and thus cause intermittent simCNC operation. To prevent this from happening, 16GB or even 32GB RAM is used.

In the case of 3-axis machines for general use, you can try to use Raspberry Pi 4B. Typically, Raspberry Pi 4B is sufficient for such machines with a considerable margin.

2. Yes, you can use measuring scales, but the question is why do you want to do it? If you intend to use this solution to get rid of, for example, the problem of non-uniform pitch of a ball screw, this is a good idea. On the other hand, if your problem is a large backlash in a drive system, the use of measuring scales is not the solution.

3. In this respect, simCNC is unimaginably advanced. The optimization and precision feature is responsible for smooth and precise movement in simCNC.

a) The optimization function works in several stages:

- removing micro sections with a different vector.

- converting any number of sections into arcs.

- converting any number of short segments with the same vector into a long segment.

b) The precision feature is responsible for connecting all remaining corners after the optimization feature with a polynomial arc.

The amount of rounding (in red) depends on the value of the set feed (parameter "F" in gcode), acceleration and axis travel, but can never be greater than the precision value. The precision value is set once in the simCNC settings or dynamically changed from the gcode level to the "G64 P..." command. For example, if you use the G64 P0.2 command, a corner in the toolpath can be rounded by a maximum of 0.2mm. Please note that we are talking about the tool path, not the detail contour, these two values are separated by the tool radius. This means that the actual rounding of the edge of the detail also depends on a diameter of the cutter.

>> Is S-curve applied in both exact stop, and CV modes?

4. The S curve is always used because it determines the dynamics of a drive, not the dynamics of a tool path.

>> Can it be adjusted via G-code/post-processor? Ie, "precise mode" or "coarse mode". I see that curve matching precision can be changed via G64,

Yes, you can use the G64 P.. command to specify the type of machining

For example:

G64 P0.5 – rough machining

G64 P0.02 – finishing (remember what I wrote at the end of point number 3)

G64 P0 – exact stop

>>but curious if other aspects could be

Physics and geometry preclude many parameters that you could manipulate from gcode.

>> Does SimCNC support, or plan to support, EtherCat or Modbus?

5. The implementation of EtherCat has been temporarily suspended due to poor availability of electronic components needed for the production of the new CSMIO/IP-EtherCat controller.

We do not currently implement Modbus in simCNC because only advanced clients use it. When we have enough time and an idea on how to implement Modbus in a friendly way for all users, we will do it. The point is that we don't want to make the same mistakes as the competition (according to our customers' reports).

6. At the moment no. This will be possible when we implement EtherCat or introduce our new simDrive drivers with support for servo motors equipped with absolute encoders.

7. The implementation plan is determined by priorities, the more users need a given feature, the greater the priority. We are currently striving to ensure that simCNC fully supports all popular machines. Currently, we do not yet have lathe and threading support, which we plan to implement in the fall.

8. We plan to release some new equipment that will cause quite a shock for customers in this price range. The first to be released is the simDrive V3 drive, which will be attractive due to:

- simBus bus instead of step/dir (huge increase in the quality of the set motion and no more lost pulses)

- encBus instead of an incremental encoder signal (no more lost pulses)

- 131k encoder instead of 10k (more pulses allow you to speed up PID regulators)

- faster PID regulators

- huge increase in precision thanks to all the above points

- built-in 3.7V cell charger

- absolute encoders

- battery backup for encoders (no more machine homing)

- new generation intelligent autotuning

- monitoring the drive load from simCNC

Secondly, a motion controller with a huge dynamically filled trajectory buffer and a more efficient processor will be released. This will allow the machine to operate uninterrupted even if the computer is restarted or freezes.

Thirdly, the motion controller mentioned above will be upgraded to the EtherCat version.

Thank you for your appreciation.

Quote from dromeister on 17 October 2023, 00:29Does SimCNC make use of multiple cores, or would the highest single core clock dictate the best performance?

Yes, the linear scales would compensate for the ballscrew inaccuracies. Backlash of course would need to be eliminated mechanically as you noted. Would these scales be able to be used with the upcoming Ethercat controller? I assume I could use the ENC module to add that capability?

Great work on the motion system. This level of optimization combined with S-curve trajectory planning is a real disruption to the market.

Thanks for taking the time to fully answer the questions, especially in such detail. Sounds like it will check off all my boxes once the Ethercat hardware you mentioned is released. I am excitedly looking forward to it!

Does SimCNC make use of multiple cores, or would the highest single core clock dictate the best performance?

Yes, the linear scales would compensate for the ballscrew inaccuracies. Backlash of course would need to be eliminated mechanically as you noted. Would these scales be able to be used with the upcoming Ethercat controller? I assume I could use the ENC module to add that capability?

Great work on the motion system. This level of optimization combined with S-curve trajectory planning is a real disruption to the market.

Thanks for taking the time to fully answer the questions, especially in such detail. Sounds like it will check off all my boxes once the Ethercat hardware you mentioned is released. I am excitedly looking forward to it!

Quote from CS-Lab Support on 17 October 2023, 15:00>> Does SimCNC make use of multiple cores, or would the highest single core clock dictate the best performance?

SimCNC generally tries to use as many cores (threads) as possible.

Unfortunately, some calculations must be performed in one thread during processing.>> Would these scales be able to be used with the upcoming Ethercat controller? I assume I could use the ENC module to add that capability?

You almost answered your question.

EtherCat offers enormous possibilities, including reading the actual position using the encoder input module (it is not easy to configure, but it is possible).

This is an encoder input module supporting EtherCat. We want to introduce such a module (along with other modules) into production in the future.>> Great work on the motion system. This level of optimization combined with S-curve trajectory planning is a real disruption to the market.

You are right, but unfortunately, not everyone is yet aware of the advantages of this solution.

What I mean here is that users do not realize that their machine can work even more smoothly, dynamically, and precisely.

Therefore, they are very surprised when they try simCNC for the first time.Regards

>> Does SimCNC make use of multiple cores, or would the highest single core clock dictate the best performance?

SimCNC generally tries to use as many cores (threads) as possible.

Unfortunately, some calculations must be performed in one thread during processing.

>> Would these scales be able to be used with the upcoming Ethercat controller? I assume I could use the ENC module to add that capability?

You almost answered your question.

EtherCat offers enormous possibilities, including reading the actual position using the encoder input module (it is not easy to configure, but it is possible).

This is an encoder input module supporting EtherCat. We want to introduce such a module (along with other modules) into production in the future.

>> Great work on the motion system. This level of optimization combined with S-curve trajectory planning is a real disruption to the market.

You are right, but unfortunately, not everyone is yet aware of the advantages of this solution.

What I mean here is that users do not realize that their machine can work even more smoothly, dynamically, and precisely.

Therefore, they are very surprised when they try simCNC for the first time.

Regards