General about the CSMIO-MPG Kit

CSMIO-MPG Set is a 6-axis ready-made solution enabling manual manipulation of the machine axes. This set combines the CSMIO-MPG module and a good-quality hand encoder. This set allows for easy, free, and, above all, intuitive movement of the axes. It was selected for users with a professional approach to using the machine. For an affordable price, they can equip their machine tool with a precise tool for quick configuration of material base (G54, G55 …), tool changer (tool length offset), as well as for manual machining or quick manual ride.

How does it work?

After pressing ENABLE button on a manual handwheel, a CSMIO-MPG module via a CSMIO/IP controller switches software (simCNC, Mach3, Mach4) to MPG mode. After switching the software to MPG mode, the CSMIO-MPG module starts continuous encoder pulses counting and also verifies digital inputs state, to which there are switches connected (of axis selection and step size). All the information are transferred through CAN bus to a CSMIO/IP motion controller, where they are changed into motion trajectory for a selected axis.

Several algorithms are watching over motion trajectory creation. The algorithms’ task is to make axis motion precise and smooth. This way prepared motion trajectory is performed by a servo drive or a stepper drive. At the same moment when an axis is moving the CSMIO/IP motion controller sends current axis position to software this way that its axis position DRO shown the current location.

Operation stability is provided by:

- the connection of the CSMIO-MPG module with a CSMIO/IP controller through CAN bus. It guarantees correct and fast transmission even in a tough industrial environment. The great advantage of CAN bus is resistance to interference also in case of much distance between devices, the resistance is assured by differential transmission and CAN bus termination (120 Ohm resistor at the beginning and the end of the CAN bus). Another advantage of the CAN bus is the ability to detect collisions and data loss by the strict control of the transmission.

- the connection of CSMIO-MPG module and handwheel with shielded cable using differential transmission for encoder pulses transfer. In this case, the differential transmission is very resistant to interference. It’s thanks to optoisolators used in encoder input of CSMIO-MPG module, the optoisolators which load the differential line correctly (differential line termination).

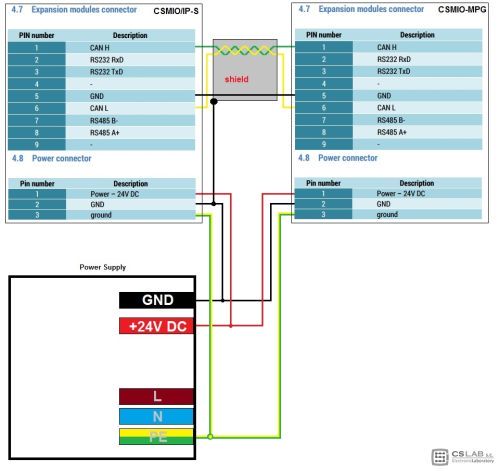

Sample CAN bus connection for CSMIO/IP-S controller and CSMIO-MPG module (based on available documentation).

Manual Pulse Generator – JOG handwheel. Easy installation

Manual Pulse Generator – JOG handwheel. Easy installation

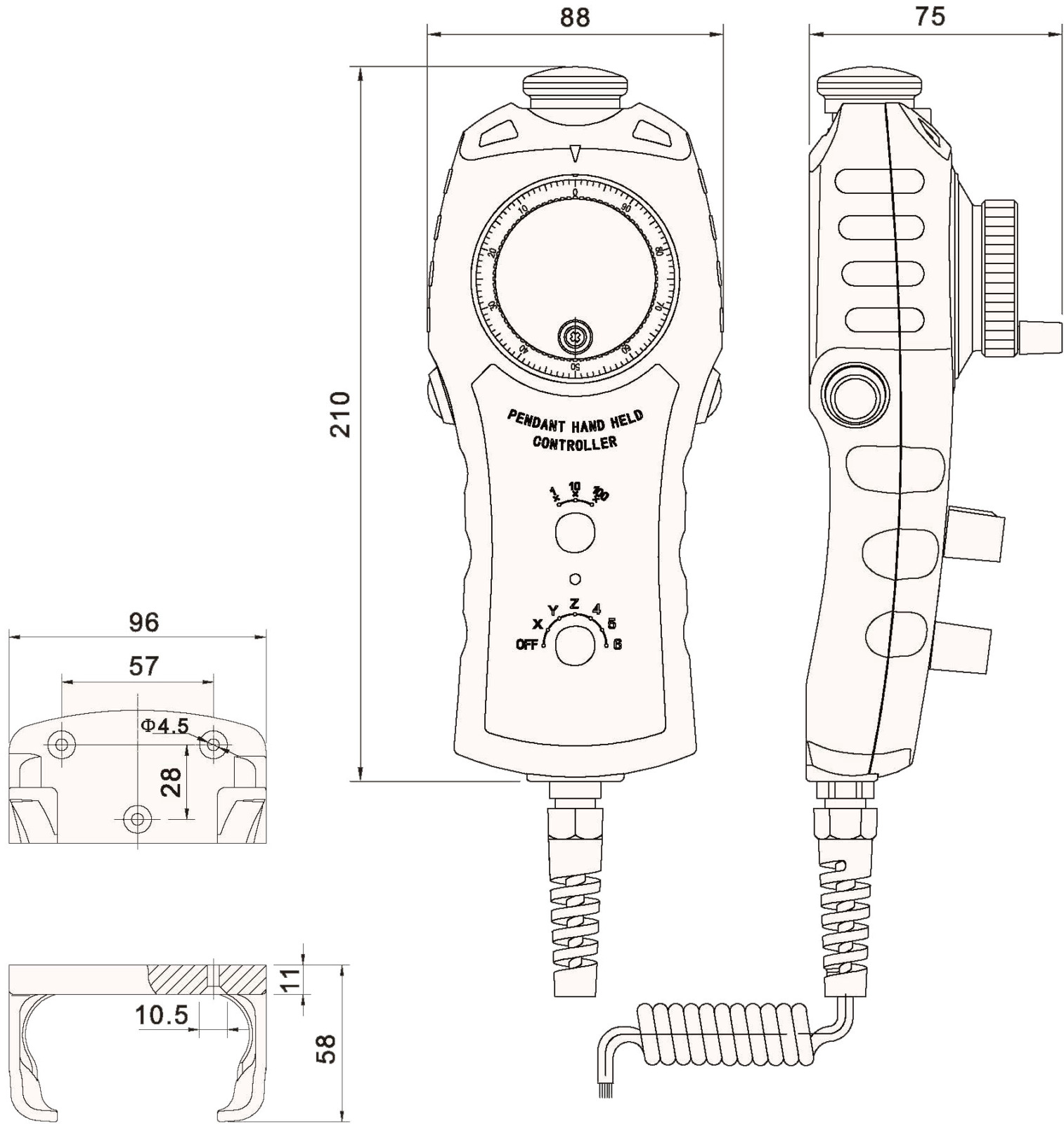

JOG handwheel is a tool for quick configuration of a material base (G54, G55 …), tool changer (tool length offset), as well as for manual machining or fast manual rides. The handwheel available in this kit is ISMM2188 (also available separately).

| ISMM2188 | – | 001 | 100 | B | – | 5 | L |

| Series | Sequence Number |

Number of Pulses |

Output Signals |

Supply Voltage |

Output Circuit |

The connection of CSMIO-MPG Kit is very simple and won’t cause any trouble even to not experienced users. It shouldn’t take more than 5 minutes to run it:

How to run it?

- Fasten the module on a DIN rail

- Place the DB25 plug of the JOG handwheel in the CSMIO-MPG module socket.

- Connect the CAN bus with the included DB9 tape

- Connect 24V DC power.

- Connect E-STOP circuit to terminals E1 and E2 (order of the connections is not important). Terminals E1 and E2 are pins of the handwheel E-STOP button.

The additional blue button is a button that allows you to perform additional functions if you use simCNC, including:

- deleting the selected axis coordinate in combination with a multi-position axis selection switch,

- triggering homing of the selected axis in combination with a multi-position axis selection switch,

- changing any value (e.g. SRO, FRO, JRO) in connection with the encoder wheel,

- and many more that you can think of.

How it’s working?

The blue button is connected to the previously unused digital input number 9 of the CSMIO-MPG module. Pressing it activates input number 9, which triggers the Python action, which triggers the macro assigned to this action. In this macro we can read the positions of the axis selection and step size switches, as well as the position and speed of the encoder. Based on this data, we can create additional functionalities.

In the case of Mach4, the situation is analogous, but here a PLC macro should be used.

It is impossible to use an additional button in Mach3.

![]()

The Main Advantages

- No settings required – CSMIO-MPG in current plugin version for Mach3 (up.to 23.01.2017) is ready to work right after installation and doesn’t need any configuration. It’s possible since digital signals have functions assigned permanently. In case of Mach4, it will be possible to create your own digital signals configuration and also to use them for purposes not related to MPG module. It means that free digital inputs can be used for example for start-stop – pause buttons connection.

- Safety system – CSMIO-MPG module is equipped with hardware E-STOP circuit. It means that the E-STOP circuit goes through the module and a manual handwheel encoder. After pressing the emergency stop button on the handwheel the circuit is opened (open circuit), what causes immediate machine stop. It’s about the same E-Stop circuit used by CSMIO/IP motion controller and and all emergency buttons mounted in a machine.

- Solid aluminum housing which dissipates heat and protects electronic circuits very well. Readable led controls on a front panel which make it easier to install and simplify diagnostics in case of any problems with switches and an encoder of a handwheel.

- The sturdy design of handwheel – it was equipped with sturdy and handy housing with excellent quality: switches manual encoder, LED indicating MPG mode work as well as ENABLE and E-STOP buttons. It can serve for many years without any issue even if it’s used regularly.

- Additional features – CSMIO-MPG module has two 0-5V analog inputs that can be used for connection of poteniometers of spindle rotary speed and axis feed rate correction. In case of 4-axis machines, the 5th axis selection switch position (B axis) and 6th position (C axis) may be used for spindle rotary speed and axis feed rate correction. The correction value is in this case adjusted with the manual handwheel encoder.

- Industry standard – CSMIO-MPG module is adapted to worldwide standards:

- Opto-isolated 24V DC digital outputs

- Opto-isolated 24V DC digital inputs

- The power supply adapted to 24VDC

![]()

Technical data

CSMIO-MPG module

| PARAMETER | VALUE |

| Number of axes | 6 |

| Digital inputs (opto-isolated) | 10 |

| Digital outputs (opto-isolated) | 2 |

| Analog inputs | 2 |

| Supply voltage | 24VDC +/-10% |

| Power consumption | 5W |

| Maximum voltage on in/out lines | 30VDC |

| Maximum load of output line | 30mA |

| Voltage range of analog inputs | 0-5 VDC |

| Maximum frequency of encoder signal | 10KHz |

| Ambient temperature range | 0oC to +60oC |

| Relative humidity (without condensation) | 10% – 95% |

Technical data of the handwheel

| ISMM2188 | – | 001 | 100 | B | – | 5 | L |

| Series | Sequence Number |

Number of Pulses |

Output Signals |

Supply Voltage |

Output Circuit |

The additional blue button is a button that allows you to perform additional functions if you use simCNC, including:

- deleting the selected axis coordinate in combination with a multi-position axis selection switch,

- triggering homing of the selected axis in combination with a multi-position axis selection switch,

- changing any value (e.g. SRO, FRO, JRO) in connection with the encoder wheel,

- and many more that you can think of.

The blue button is connected to the previously unused digital input number 9 of the CSMIO-MPG module. Pressing it activates input number 9, which triggers the Python action, which triggers the macro assigned to this action. In this macro we can read the positions of the axis selection and step size switches, as well as the position and speed of the encoder. Based on this data, we can create additional functionalities.

In the case of Mach4, the situation is analogous, but here a PLC macro should be used.

It is impossible to use an additional button in Mach3.

| ELECTRICAL SPECIFICATION | |

| Output wave | Square wave |

| Output signals | A,B, (Line driver output A,A(_),B,B(_), phase) |

| Current consumption | ≤100mA |

| Response Frequency | 0~20KHz |

| Output phase difference | 90° ± 45° |

| Supply voltage | 5VDC and 24 VDC |

| Signal level | VH ≥ 85%Vcc, VL ≤ 0.3V |

| Number of pulses | 100 |

| MECHANICAL SPECIFICATION | |

| Signal position | 2kind |

| Speed without sealing | 500 rmp |

| Starting torque w/o sealing | ≤2.0x 10-2 ~6.0x 10-2 Nm (+25°C) |

| Shock resistance | 980m/s2, 6ms, 2 times each on XYZ |

| Weight | Appr. 740g (incl. 1.5 meter cable) |

You will find more details in Download tab (documentation)

Purpose

CSMIO-MPG Kit is recommended to users/companies who:

- retrofit original CNC machines and what to get full functionality by using the handwheel encoder function,

- build new machines and want to raise their utility value implementing solutions previously found in CNC machines of well-known manufacturers.

- build machines with a large working area and are looking for solutions that would allow a machine operator to move away from a control panel and still keeping control over machine axes (in the MPG/JOG mode), axis feed rate, spindle speed, and an emergency stop button.

CSMIO-MPG module can be successfully used in CNC machines of any type, especially recommended for milling and turning machines.

In The Box

![]()

Dimension of the CSMIO-MPG Kit

![]()

Download

CSMIO-MPG® v2 Module for manual axis operation – JOG (for all CSMIO/IP models)

MPG Handwheel ISMM2188 Manual Pulse Generator JOG encoder