CS-Lab Support Forum for CNC Community

Help to run this brand-new forum and stay with us.

Ask your questions, we are here to help!

simCNC feature ideas

Quote from andre on 11 June 2023, 20:30Good evening!

I am not sure if this is the right place or mode to bring forward my ideas, but I am trying my luck...

As you know I am relatively new to simCNC and still adjusting the software to my needs. Here are some points which I think will make the software even greater:

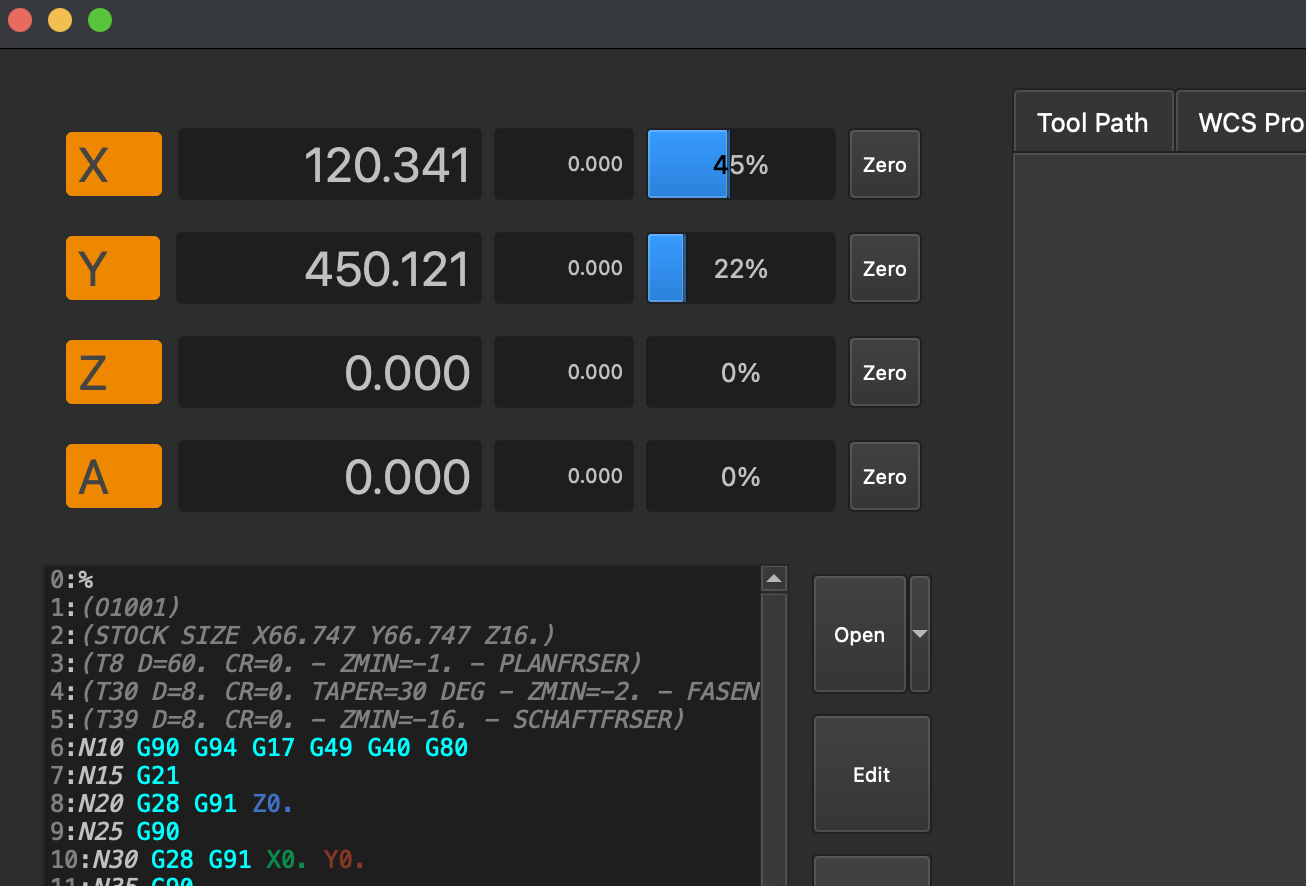

- Tool path view

- Default zoom to workpiece rather than whole machine

- Can it be controlled via Python? i.e. a button to change the view to one of the preset values or completely free positioning of the camera?

- On-Screen Keyboard specific to the clicked field to enable use of touch screens without an external keyboard

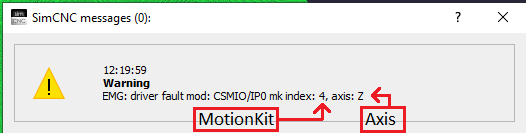

- Map drive alert to motion kits rather than axis My machine has two drives for X and I can only map one alarm input

- Make air seal / spindle pressurization a function in the configuration

including a delayed switch-off I have adjusted my M3/M4 macros, but when running the spindle from GUI this themes to not use the macros but triggers the spindle internally- An hour meter separately tracking: controller hours, GCode execution, spindle time

Would be good to use it for lubrication or tracking maintenance intervals- Min/max position variable for loaded GCode

- Based on 6: a „way to go“ variable when running GCode,

showing how much more distance will still be traveled- Enable/Disable all Softlimits via button

Currently only possible via CheckBox.- Progress bar flexible denominator

Allow the increments to be shown to be adjusted. I am trying to display spindle load in the GUI, min/max can be adjusted but the increments are quite large when showing an analog 0-10v signal.

The following points are some things I noticed not functioning as expected (W10 22H2 built 19045.2965 with simCNC 3.5 beta 4)

- Jog/MPG disable via digital input does not work. Jog remains on.

- Scroll card is not to functioning as expected. Is there a trick?

- Axis velocity variable is displayed in a strange numbe format. My idea was to show the currently velocity via a progress bar for each axis. Screenshot shows what I want to achieve. At speed 0, its currently showing a negative fractional number.

- Softlimit status makes LED button flicker

if you put softlimit status as LED status, it flickers badly

Best regards,

André

Good evening!

I am not sure if this is the right place or mode to bring forward my ideas, but I am trying my luck...

As you know I am relatively new to simCNC and still adjusting the software to my needs. Here are some points which I think will make the software even greater:

- Tool path view

- Default zoom to workpiece rather than whole machine

- Can it be controlled via Python? i.e. a button to change the view to one of the preset values or completely free positioning of the camera?

- On-Screen Keyboard specific to the clicked field to enable use of touch screens without an external keyboard

- Map drive alert to motion kits rather than axis My machine has two drives for X and I can only map one alarm input

- Make air seal / spindle pressurization a function in the configuration

including a delayed switch-off I have adjusted my M3/M4 macros, but when running the spindle from GUI this themes to not use the macros but triggers the spindle internally - An hour meter separately tracking: controller hours, GCode execution, spindle time

Would be good to use it for lubrication or tracking maintenance intervals - Min/max position variable for loaded GCode

- Based on 6: a „way to go“ variable when running GCode,

showing how much more distance will still be traveled - Enable/Disable all Softlimits via button

Currently only possible via CheckBox. - Progress bar flexible denominator

Allow the increments to be shown to be adjusted. I am trying to display spindle load in the GUI, min/max can be adjusted but the increments are quite large when showing an analog 0-10v signal.

The following points are some things I noticed not functioning as expected (W10 22H2 built 19045.2965 with simCNC 3.5 beta 4)

- Jog/MPG disable via digital input does not work. Jog remains on.

- Scroll card is not to functioning as expected. Is there a trick?

- Axis velocity variable is displayed in a strange numbe format. My idea was to show the currently velocity via a progress bar for each axis. Screenshot shows what I want to achieve. At speed 0, its currently showing a negative fractional number.

- Softlimit status makes LED button flicker

if you put softlimit status as LED status, it flickers badly

Best regards,

André

Quote from CS-Lab Support on 13 June 2023, 08:34>> Default zoom to workpiece rather than whole machine

The view of a workpiece was what users mainly wanted. I will add the idea of a view of a whole machine to the to-do list (ticket #512).

>> Can it be controlled via Python?

There is no such possibility.

>> On-Screen Keyboard specific to the clicked field to enable use of touch screens without an external keyboard

Something like this is planned (ticket #335).

>> Map drive alert to motion kits rather than axis

The drive error message is double because some users wanted to know which MotionKit had the problem, and others wanted to know which axis was affected.

>> My machine has two drives for X and I can only map one alarm input

It's not like that. Each MotionKit has its Alarm signal.

>> Make air seal / spindle pressurization a function in the configuration

I don't understand what you mean, so I don't know how to evaluate this idea. Try to expand your thought.

>> have adjusted my M3/M4 macros, but when running the spindle from GUI this themes to not use the macros but triggers the spindle internally

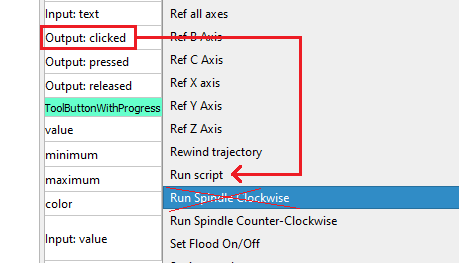

The buttons for a spindle on the screen do not execute M3 because they are only used to start the spindle manually. You must modify the screen if you want this button to run M3 macros. Start the screen editor, click on the spindle button, and change the indicated parameter:

When you do this, you will be asked to indicate a macro. Please find the macro below. It runs your modified M3 and M5 macros.

Spindle control from the screen

>> An hour meter separately tracking: controller hours, GCode execution, spindle time

> Would be good to use it for lubrication or tracking maintenance intervals

We plan to add this (ticket #157).

>> Min/max position variable for loaded GCode

We've been thinking about this for some time (ticket #513)

>> a „way to go“ variable when running GCode,

>> showing how much more distance will still be traveled

Please explain to me:

- How would it work (I guess, but I want to be sure)

- When is it useful, and how often?

>> Enable/Disable all Softlimits via button Currently only possible via CheckBox.

It is possible, but you have to do as in the case of the button for a spindle (I described above). To read the status of the global soft limit, use d.areAllSoftLimitsIgnored( ). To set a global soft limit, use d.ignoreAllSoftLimits( bool ignore )

>> Allow the increments to be shown to be adjusted.

>> I am trying to display spindle load in the GUI, min/max can be adjusted but the increments are quite large when showing an analog 0-10v signal.

I don't understand what your problem is with this. It's quite a simple issue, and that's why I don't understand what the problem is or I don't know what you want to achieve.

>> Jog/MPG disable via digital input does not work. Jog remains on.

I have not observed this problem.

>> Default zoom to workpiece rather than whole machine

The view of a workpiece was what users mainly wanted. I will add the idea of a view of a whole machine to the to-do list (ticket #512).

>> Can it be controlled via Python?

There is no such possibility.

>> On-Screen Keyboard specific to the clicked field to enable use of touch screens without an external keyboard

Something like this is planned (ticket #335).

>> Map drive alert to motion kits rather than axis

The drive error message is double because some users wanted to know which MotionKit had the problem, and others wanted to know which axis was affected.

>> My machine has two drives for X and I can only map one alarm input

It's not like that. Each MotionKit has its Alarm signal.

>> Make air seal / spindle pressurization a function in the configuration

I don't understand what you mean, so I don't know how to evaluate this idea. Try to expand your thought.

>> have adjusted my M3/M4 macros, but when running the spindle from GUI this themes to not use the macros but triggers the spindle internally

The buttons for a spindle on the screen do not execute M3 because they are only used to start the spindle manually. You must modify the screen if you want this button to run M3 macros. Start the screen editor, click on the spindle button, and change the indicated parameter:

When you do this, you will be asked to indicate a macro. Please find the macro below. It runs your modified M3 and M5 macros.

Spindle control from the screen

>> An hour meter separately tracking: controller hours, GCode execution, spindle time

> Would be good to use it for lubrication or tracking maintenance intervals

We plan to add this (ticket #157).

>> Min/max position variable for loaded GCode

We've been thinking about this for some time (ticket #513)

>> a „way to go“ variable when running GCode,

>> showing how much more distance will still be traveled

Please explain to me:

- How would it work (I guess, but I want to be sure)

- When is it useful, and how often?

>> Enable/Disable all Softlimits via button Currently only possible via CheckBox.

It is possible, but you have to do as in the case of the button for a spindle (I described above). To read the status of the global soft limit, use d.areAllSoftLimitsIgnored( ). To set a global soft limit, use d.ignoreAllSoftLimits( bool ignore )

>> Allow the increments to be shown to be adjusted.

>> I am trying to display spindle load in the GUI, min/max can be adjusted but the increments are quite large when showing an analog 0-10v signal.

I don't understand what your problem is with this. It's quite a simple issue, and that's why I don't understand what the problem is or I don't know what you want to achieve.

>> Jog/MPG disable via digital input does not work. Jog remains on.

I have not observed this problem.

Quote from dylan1024 on 13 June 2023, 09:39>> a „way to go“ variable when running GCode,

>> showing how much more distance will still be traveled

Please explain to me:

- How would it work (I guess, but I want to be sure)

- When is it useful, and how often?

My take in it:

It is VERY useful, it adds another level of safety and feedback especially when running a new program.

It displays how far each axis has left to travel for the currently executing line of Gcode.if Z is currently at 200 and the Gcode line that runs is a G1 Z -150 F100 then, as that line is run distance to go will start at -150 and tend to zero as the axis approaches the commanded position. here is a GIF of a Fanuc screen with distance to go on the right https://www.inventcom.net/support/fanuc/machine-data

So what does this give the operator? it lets you sanity check things: Z is busy plunging, the collet nut looks 1mm to crashing a clamp, distance to go shows -0.2 so its going to be fine.....if distance to go is showing -5 then its not going to be fine

Dylan

>> a „way to go“ variable when running GCode,

>> showing how much more distance will still be traveled

Please explain to me:

- How would it work (I guess, but I want to be sure)

- When is it useful, and how often?

My take in it:

It is VERY useful, it adds another level of safety and feedback especially when running a new program.

It displays how far each axis has left to travel for the currently executing line of Gcode.

if Z is currently at 200 and the Gcode line that runs is a G1 Z -150 F100 then, as that line is run distance to go will start at -150 and tend to zero as the axis approaches the commanded position. here is a GIF of a Fanuc screen with distance to go on the right https://www.inventcom.net/support/fanuc/machine-data

So what does this give the operator? it lets you sanity check things: Z is busy plunging, the collet nut looks 1mm to crashing a clamp, distance to go shows -0.2 so its going to be fine.....if distance to go is showing -5 then its not going to be fine

Dylan

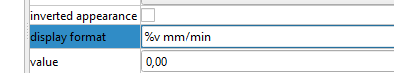

Quote from CS-Lab Support on 13 June 2023, 14:17>> Axis velocity variable is displayed in a strange numbe format. My idea was to show the currently velocity via a progress bar for each axis.

>> Screenshot shows what I want to achieve. At speed 0, its currently showing a negative fractional number.

It turned out that there was really only one issue and it was fixed in 3.500 Beta 5, which will be released soon.

I'll just add for future reference that you should use "Display format" %v. %v causes the progress bar to display the total value of the axis velocity (in your case).

You can also add the unit %v mm/min :

Then you will get this effect:

Regards,

>> Axis velocity variable is displayed in a strange numbe format. My idea was to show the currently velocity via a progress bar for each axis.

>> Screenshot shows what I want to achieve. At speed 0, its currently showing a negative fractional number.

It turned out that there was really only one issue and it was fixed in 3.500 Beta 5, which will be released soon.

I'll just add for future reference that you should use "Display format" %v. %v causes the progress bar to display the total value of the axis velocity (in your case).

You can also add the unit %v mm/min :

Then you will get this effect:

Regards,

Quote from Villu1 on 13 June 2023, 18:10Hello!

Im not sure thats covered, but its really annoying, maybe its just me and my setupt, BUT

If there is error outside softlimit, is it possible to add more info for what axle is outside?

Mine has usually problems with z axis for some reason.

When my z is at home and on zero then program program will give me outside soft limit error. My z axis has to be atleast -40mm, then its no problems.

Just idea to get more info what axis is outside, sometimes when i resurface my spoilboard, it will give me the same error, but no info what axis is troubleshooting.

Regards

Hello!

Im not sure thats covered, but its really annoying, maybe its just me and my setupt, BUT

If there is error outside softlimit, is it possible to add more info for what axle is outside?

Mine has usually problems with z axis for some reason.

When my z is at home and on zero then program program will give me outside soft limit error. My z axis has to be atleast -40mm, then its no problems.

Just idea to get more info what axis is outside, sometimes when i resurface my spoilboard, it will give me the same error, but no info what axis is troubleshooting.

Regards

Quote from andre on 13 June 2023, 20:10

Thank you for the very detailed feedback on my points!

Here are some more information to clarify my ideas:Quote from andre on 11 June 2023, 20:304. Make air seal / spindle pressurization a function in the configuration

including a delayed switch-off I have adjusted my M3/M4 macros, but when running the spindle from GUI this themes to not use the macros but triggers the spindle internallyMany high frequency spindles, especially for machining wood, have a bearing overpressurization or air seal. It flushes air through the spindle nose to keep any dust out. I have already adjusted the M3/M4/M5 Macros to switch a valve before spindle run up. Nevertheless, it would be nice if this could be a standard feature on spindle run. Not really required for me, but might be nice for others.

Quote from CS-Lab Support on 13 June 2023, 14:17>> Axis velocity variable is displayed in a strange numbe format. My idea was to show the currently velocity via a progress bar for each axis.

>> Screenshot shows what I want to achieve. At speed 0, its currently showing a negative fractional number.

It turned out that there was really only one issue and it was fixed in 3.500 Beta 5, which will be released soon.

I'll just add for future reference that you should use "Display format" %v. %v causes the progress bar to display the total value of the axis velocity (in your case).

Thank you for the quick fix!

Formatting itself is clear 🙂

Quote from dylan1024 on 13 June 2023, 09:39>> a „way to go“ variable when running GCode,

>> showing how much more distance will still be traveled

Please explain to me:

- How would it work (I guess, but I want to be sure)

- When is it useful, and how often?

My take in it:

It is VERY useful, it adds another level of safety and feedback especially when running a new program.

It displays how far each axis has left to travel for the currently executing line of Gcode....

Thank you very much Dylan, couldn't have put it any better!

Quote from CS-Lab Support on 13 June 2023, 08:34>> Map drive alert to motion kits rather than axis

The drive error message is double because some users wanted to know which MotionKit had the problem, and others wanted to know which axis was affected.

It's not like that. Each MotionKit has its Alarm signal.

Sorry, I may have mixed up something there. Thanks for checking.

Quote from CS-Lab Support on 13 June 2023, 08:34>> Allow the increments to be shown to be adjusted.

>> I am trying to display spindle load in the GUI, min/max can be adjusted but the increments are quite large when showing an analog 0-10v signal.

I don't understand what your problem is with this. It's quite a simple issue, and that's why I don't understand what the problem is or I don't know what you want to achieve.

A progress bar displaying a 0-10V analog input has very large increments - I havn't counted, but it's like 10-15 steps only. It would be nice to be able to control the precision of the progress bar to get finer increments. I can create some screenshots from real life values.

Quote from CS-Lab Support on 13 June 2023, 08:34>> Default zoom to workpiece rather than whole machine

The view of a workpiece was what users mainly wanted. I will add the idea of a view of a whole machine to the to-do list (ticket #512).

Thank you! Especially helpful with larger machines (X=2.300mm in my case) to identfy where the work piece will be located. For me this was always a good sanity check before starting a cycle.

Best regards,

André

Thank you for the very detailed feedback on my points!

Here are some more information to clarify my ideas:

Quote from andre on 11 June 2023, 20:304. Make air seal / spindle pressurization a function in the configuration

including a delayed switch-off I have adjusted my M3/M4 macros, but when running the spindle from GUI this themes to not use the macros but triggers the spindle internally

Many high frequency spindles, especially for machining wood, have a bearing overpressurization or air seal. It flushes air through the spindle nose to keep any dust out. I have already adjusted the M3/M4/M5 Macros to switch a valve before spindle run up. Nevertheless, it would be nice if this could be a standard feature on spindle run. Not really required for me, but might be nice for others.

Quote from CS-Lab Support on 13 June 2023, 14:17>> Axis velocity variable is displayed in a strange numbe format. My idea was to show the currently velocity via a progress bar for each axis.

>> Screenshot shows what I want to achieve. At speed 0, its currently showing a negative fractional number.

It turned out that there was really only one issue and it was fixed in 3.500 Beta 5, which will be released soon.

I'll just add for future reference that you should use "Display format" %v. %v causes the progress bar to display the total value of the axis velocity (in your case).

Thank you for the quick fix!

Formatting itself is clear 🙂

Quote from dylan1024 on 13 June 2023, 09:39>> a „way to go“ variable when running GCode,

>> showing how much more distance will still be traveled

Please explain to me:

- How would it work (I guess, but I want to be sure)

- When is it useful, and how often?

My take in it:

It is VERY useful, it adds another level of safety and feedback especially when running a new program.

It displays how far each axis has left to travel for the currently executing line of Gcode....

Thank you very much Dylan, couldn't have put it any better!

Quote from CS-Lab Support on 13 June 2023, 08:34>> Map drive alert to motion kits rather than axis

The drive error message is double because some users wanted to know which MotionKit had the problem, and others wanted to know which axis was affected.

It's not like that. Each MotionKit has its Alarm signal.

Sorry, I may have mixed up something there. Thanks for checking.

Quote from CS-Lab Support on 13 June 2023, 08:34>> Allow the increments to be shown to be adjusted.

>> I am trying to display spindle load in the GUI, min/max can be adjusted but the increments are quite large when showing an analog 0-10v signal.

I don't understand what your problem is with this. It's quite a simple issue, and that's why I don't understand what the problem is or I don't know what you want to achieve.

A progress bar displaying a 0-10V analog input has very large increments - I havn't counted, but it's like 10-15 steps only. It would be nice to be able to control the precision of the progress bar to get finer increments. I can create some screenshots from real life values.

Quote from CS-Lab Support on 13 June 2023, 08:34>> Default zoom to workpiece rather than whole machine

The view of a workpiece was what users mainly wanted. I will add the idea of a view of a whole machine to the to-do list (ticket #512).

Thank you! Especially helpful with larger machines (X=2.300mm in my case) to identfy where the work piece will be located. For me this was always a good sanity check before starting a cycle.

Best regards,

André

Quote from CS-Lab Support on 14 June 2023, 11:42>> if Z is currently at 200 and the Gcode line that runs is a G1 Z -150 F100 then,

>> as that line is run distance to go will start at -150 and tend to zero as the axis approaches the commanded position.

>> here is a GIF of a Fanuc screen with distance to go on the right

Since the current Z-axis position is 200 and the position to be reached is -150, shouldn't the distance to go be -350?

-150 – 200 = -350

>> if Z is currently at 200 and the Gcode line that runs is a G1 Z -150 F100 then,

>> as that line is run distance to go will start at -150 and tend to zero as the axis approaches the commanded position.

>> here is a GIF of a Fanuc screen with distance to go on the right

Since the current Z-axis position is 200 and the position to be reached is -150, shouldn't the distance to go be -350?

-150 – 200 = -350

Quote from CS-Lab Support on 14 June 2023, 14:49>> Many high frequency spindles, especially for machining wood, have a bearing overpressurization or air seal.

>> It flushes air through the spindle nose to keep any dust out. I have already adjusted the M3/M4/M5 Macros to switch a valve before spindle run up.

>> Nevertheless, it would be nice if this could be a standard feature on spindle run. Not really required for me, but might be nice for others.

Now I understand what you meant. Unfortunately, we are against adding the spindle air flushing to the simCNC settings. I know from experience that the air flushing of the spindle should be controlled from the M6 macro, it gives freedom and a free hand to a user.

In my career, I have encountered so many solutions that I cannot imagine imposing or proposing something to users by force.

>> Thank you very much Dylan, couldn't have put it any better!

I'm going to need more clarification here. I already asked Dylan a question.

>> A progress bar displaying a 0-10V analog input has very large increments - I havn't counted, but it's like 10-15 steps only.

>> It would be nice to be able to control the precision of the progress bar to get finer increments.

>> I can create some screenshots from real life values.

I think I already know what the problem is. It seems that the voltage value from the analog input is transferred to the screen in integer form, which means that the progress bar is divided into only 10 parts (0V, 1V, 2V……..10V).

I will discuss this with our developers to change it so that you can display the voltage as a percentage (0%, 1%, 2%.........100%)

>> Many high frequency spindles, especially for machining wood, have a bearing overpressurization or air seal.

>> It flushes air through the spindle nose to keep any dust out. I have already adjusted the M3/M4/M5 Macros to switch a valve before spindle run up.

>> Nevertheless, it would be nice if this could be a standard feature on spindle run. Not really required for me, but might be nice for others.

Now I understand what you meant. Unfortunately, we are against adding the spindle air flushing to the simCNC settings. I know from experience that the air flushing of the spindle should be controlled from the M6 macro, it gives freedom and a free hand to a user.

In my career, I have encountered so many solutions that I cannot imagine imposing or proposing something to users by force.

>> Thank you very much Dylan, couldn't have put it any better!

I'm going to need more clarification here. I already asked Dylan a question.

>> A progress bar displaying a 0-10V analog input has very large increments - I havn't counted, but it's like 10-15 steps only.

>> It would be nice to be able to control the precision of the progress bar to get finer increments.

>> I can create some screenshots from real life values.

I think I already know what the problem is. It seems that the voltage value from the analog input is transferred to the screen in integer form, which means that the progress bar is divided into only 10 parts (0V, 1V, 2V……..10V).

I will discuss this with our developers to change it so that you can display the voltage as a percentage (0%, 1%, 2%.........100%)

Quote from CS-Lab Support on 15 June 2023, 08:45>> A progress bar displaying a 0-10V analog input has very large increments - I havn't counted, but it's like 10-15 steps only.

>> It would be nice to be able to control the precision of the progress bar to get finer increments.

>> I can create some screenshots from real life values.

I talked to the developer and unfortunately, the "ProgressBar" for both %v and %p formats always expects an integer value (I was under the illusion that %p wasn't the case). This means that the minimum resolution of the Progress Bar will always be 1. Unfortunately, we can't do anything about it.

A sure solution (not very elegant) is to write a macro that will multiply the value of the analog signal voltage x 10. This will cause that "ProgressBar" will still work with a resolution of 1 but in the range from 0 to 100. This will give decent visual effects

The only right solution (elegant and comfortable) is to create a new object acting like "Analog IO indicator" but horizontal and longitudinal like "ProgressBar."

I added to our system a request to create such an object for the GUI (ticket #518).

I mention the "Analog IO indicator" because it is this object that is used to display the float type value (e.g., voltage value of the analog signal).

Consider whether you can temporarily use the "Analog IO indicator", and when we create our own object, you will use it.

>> A progress bar displaying a 0-10V analog input has very large increments - I havn't counted, but it's like 10-15 steps only.

>> It would be nice to be able to control the precision of the progress bar to get finer increments.

>> I can create some screenshots from real life values.

I talked to the developer and unfortunately, the "ProgressBar" for both %v and %p formats always expects an integer value (I was under the illusion that %p wasn't the case). This means that the minimum resolution of the Progress Bar will always be 1. Unfortunately, we can't do anything about it.

A sure solution (not very elegant) is to write a macro that will multiply the value of the analog signal voltage x 10. This will cause that "ProgressBar" will still work with a resolution of 1 but in the range from 0 to 100. This will give decent visual effects

The only right solution (elegant and comfortable) is to create a new object acting like "Analog IO indicator" but horizontal and longitudinal like "ProgressBar."

I added to our system a request to create such an object for the GUI (ticket #518).

I mention the "Analog IO indicator" because it is this object that is used to display the float type value (e.g., voltage value of the analog signal).

Consider whether you can temporarily use the "Analog IO indicator", and when we create our own object, you will use it.

Quote from andre on 15 June 2023, 11:06Thanks for all the explanations and details!

Progress bar

For the time being I will try the macro idea, no problem. I guess there will be some latency, but should be okay for this purpose.

Overall the spindle load display is not mission critical to me.Jog enable via DigitalIn

Will check later on today at my machine. Just to clarify: Does this affect both Jog and MPG oder just Jog (via keyboard AND via buttons on screen)?Best regards,

André

Thanks for all the explanations and details!

Progress bar

For the time being I will try the macro idea, no problem. I guess there will be some latency, but should be okay for this purpose.

Overall the spindle load display is not mission critical to me.

Jog enable via DigitalIn

Will check later on today at my machine. Just to clarify: Does this affect both Jog and MPG oder just Jog (via keyboard AND via buttons on screen)?

Best regards,

André